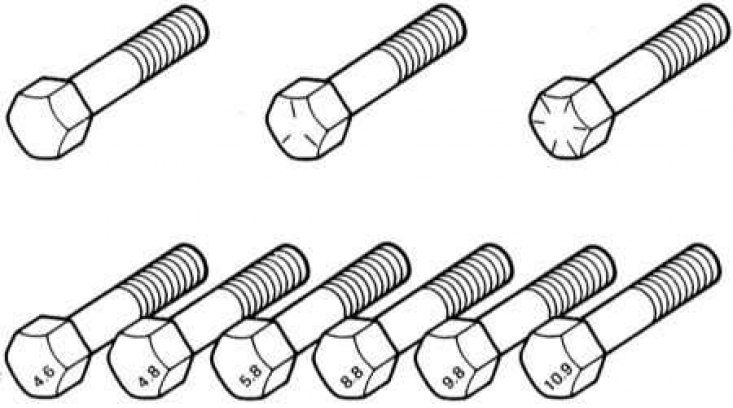

Bolt grade marking (top - standard / SAE / USS, bottom - metric)

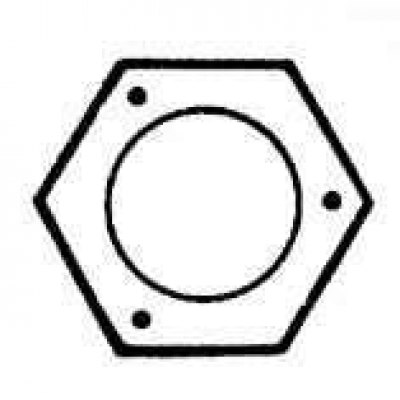

Strength class marking for standard hex nuts

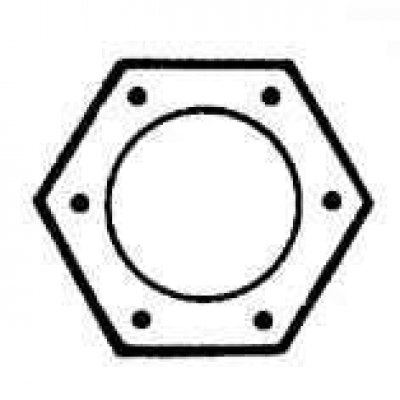

Property class marking for metric hex nuts

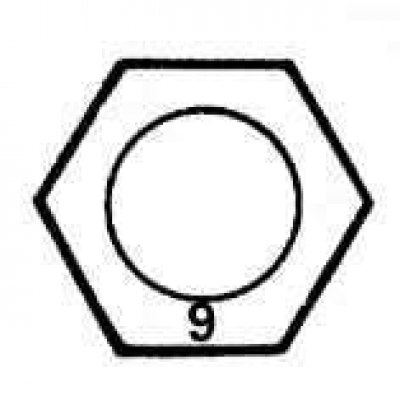

Strength class marking for metric studs

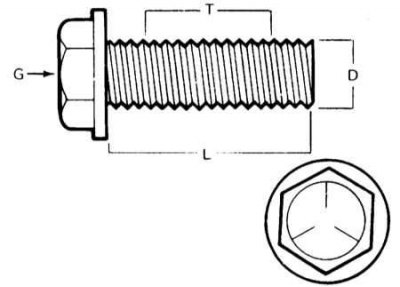

Dimensions/marking of strength class standard (SAE and USS) bolts: G - strength class marking; L - length (in inches); T - thread pitch (number of threads per inch); D - nominal diameter (in inches)

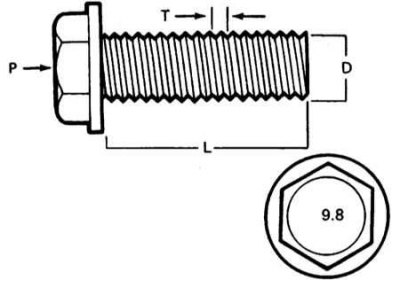

Dimensions/marking of the property class of metric bolts: Pm - strength class; L - length (in mm); T - thread pitch (distance between adjacent turns in mm); D - nominal diameter (in mm)

Service technology

There are several methods for performing vehicle maintenance and repair procedures, which the reader will find references in the text of this manual. Following them will make the work of an amateur mechanic more efficient, will allow the best organization and high-quality performance of various technical procedures and will be the key to a thorough and complete implementation of all necessary work.

Fasteners

Fasteners are nuts, bolts, studs and screws that are used to connect two or more parts together. There are a few things to keep in mind when working with fasteners. In almost any threaded fastener, one or another type of locking and locking devices is used. These can be lock washers, locknuts, lock flags, or thread locking compound. All fasteners used must be absolutely clean and straight, with intact threads and unrounded corners of the hex heads on which the wrench is put on. It should be a rule to replace damaged nuts and bolts with new ones without fail. Special self-locking nuts with nylon or fiber inserts cannot be reused, as they lose their locking properties when released and must always be replaced during assembly.

"addicted" fasteners in order to facilitate unscrewing and to avoid damage before giving back must be treated with a special penetrating compound. Many mechanics prefer to use turpentine for this purpose, which is conveniently applied from a special small canister with a long spout. After wetting the fasteners with a penetrating compound, allow the compound to thoroughly soak the oxidized contact layer for several minutes. Heavily rusted fasteners can be cut down with a chisel, cut down with a hacksaw or removed using a special wrench.

When cutting off the bolt head or breaking off the stud on the assembly, the rest of the threaded part can be drilled out or removed using a special extractor. Most bodyshops can take on this as well as others (e.g. repairing stripped threads in threaded holes), repair procedures.

Flat washers and lock washers must always be reinstalled in their original positions when reassembling. Always replace damaged washers with new ones. Between lock washer and soft metal surface (e.g. aluminum), thin sheet metal or plastic, flat washers should always be installed.

Fastener dimensions

For many reasons, automotive manufacturers are increasingly adopting metric fasteners. However, it is important to know the difference between the sometimes used standard (also called American, or SAE standard) and more universal in the system of measures with metric fasteners, since, despite the external similarity, they are not interchangeable.

All bolts, both standard and metric, are classified by diameter, thread pitch and length. For example, a standard 1/2-13x1 bolt is half an inch in diameter, 13 threads per inch, and 1 inch long. Metric bolt M12-1.75x25 has a diameter of 12 mm, thread pitch (distance between adjacent turns) 1.75 mm and 25 mm long. Both bolts are externally almost identical, but are not interchangeable.

In addition to the features listed, both metric and standard bolts can be identified by looking at the head. To begin with, the distance between the flats of the head of a metric bolt is measured in mm, while for a standard bolt it is in inches (the same is true for nuts). As a consequence, a standard wrench is not suitable for use with metric fasteners, and vice versa. In addition, the heads of most standard bolts usually have radial notches that determine the maximum allowable tightening torque of the bolt (degree of strength). The more notches, the higher the allowable force (on vehicles, bolts of strength class 0 to 5 are usually used). The strength class of metric bolts is determined by a numerical code. Code numbers are usually cast, as on standard fasteners, on the bolt head (on vehicles, bolts of strength classes 8.8, 9.8, and 10.9 are usually used).

Also, according to the marks of the strength class, standard nuts can be distinguished from metric ones. To identify the strength class of standard nuts, dot marks are used, stamped on one of the end surfaces of the nut, while metric nuts are marked using again a digital code. The greater the number of points, or the greater the value of the digital code, the higher the allowable tightening torque of the nut.

The ends of metric studs are also marked according to their strength class. A digital code is applied to large studs, while smaller ones are marked in the form of geometric shapes.

It should be noted that a significant part of the fasteners, especially the strength class from 0 to 2, is not marked at all. In this case, the only way to distinguish a standard fastener from a metric fastener is to measure the thread pitch, or compare the thread with a uniquely identified one.

Standard fasteners are also often referred to as SAE fasteners, as opposed to metric fasteners, however, it should be remembered that only small fasteners fall under the SAE classification. Large fasteners with non-metric threads are American standard fasteners (USS).

Since fasteners of the same geometric size (both standard and metric) may have different strength classes, when replacing bolts, nuts and studs on a car, attention should be paid to the conformity of the strength class of the new fastener being installed with the strength class of the old one.

Procedure and procedure for tightening threaded connections

The tightening of most threaded connections should be done with the forces determined by the requirements of the Specifications given at the beginning of each Chapter of this Manual (fastener tightening force is understood as the torque applied to it when tightening). Over-tightening the fastener may break the integrity of the fastener, while under-tightening it leads to insecure connection of the mating components. Bolts, screws and studs, depending on the material from which they are made and the diameter of the threaded part, usually have strictly defined permissible tightening forces, many of which, as already mentioned above, are given in the Specifications at the beginning of each Chapter. Strictly adhere to the recommendations given on the tightening forces of the fasteners used on the vehicle. For tightening fasteners not mentioned in the Specifications, use the torque chart below. The values given in the table are based on fasteners of strength classes 2 and 3 (Higher grade fasteners allow for more tightening), in addition, it is understood that the tightening of the dry (with unlubricated thread) fasteners screwed into steel or cast (not aluminum) detail.

Metric thread sizes

| M-6 | 9 -12 Nm |

| M-8 | 19 - 28 Nm |

| M-10 | 38 - 54 Nm |

| M-12 | 68 - 96 Nm |

| M-14 | 109 - 154 Nm |

Pipe thread sizes

| 1/8 | 7 -10 Nm |

| 1/4 | 17 - 24 Nm |

| 3/8 | 30 - 44 Nm |

| 1/2 | 34 - 47 Nm |

American standard thread sizes

| 1/4 - 20 | 9 -12 Nm |

| 5/16 - 18 | 17 - 24 Nm |

| 5/16 - 24 | 19 - 27 Nm |

| 3/8 - 16 | 30 - 43 Nm |

| 3/8 - 24 | 37 - 51 Nm |

| 7/16 - 24 | 55 - 74 Nm |

| 7/16 - 20 | 55 - 81 Nm |

| 1/2 - 13 | 75 - 108 Nm |

Fasteners located around the perimeter of any part (such as cylinder head bolts, oil pan and various covers) in order to avoid deformation of the part, it must be given and tightened in a strictly defined order. The procedure for tightening and retracting such fasteners is given in the relevant Chapters of the Guide. Unless a special order is specified, the following instructions should be followed to avoid distortion of the component. In the first stage, all bolts or nuts must be finger-tight. Further, each of them in turn must be tightened for another full turn, and the transition from one bolt / nut to another must be carried out in a diagonal order (criss-cross). Then, returning to the first bolt / nut, you should repeat the procedure in the same order, tightening the fasteners another half turn. Continue the procedure, tightening each bolt/nut, this time a quarter of a turn at a time, until they are all tightened to the required torque. When releasing fasteners, proceed in a similar manner, but in reverse order.

Disassembly of components

The disassembly of all components must be carried out in such a manner that, during assembly, each part can be installed in its original place and in the correct way. Remember the characteristic external features of the assembly, if necessary, make a landing marking of parts that can be installed in place in an ambiguous way (e.g. grooved thrust washer on the shaft). It's a good idea to place the removed parts on a clean work surface in the order in which they were removed. It will also be useful to draw up simple schematic sketches or take step-by-step photographs of the component to be dismantled.

When giving fasteners, try to mark its original position on the assembly. Often, reinstalling fasteners and washers immediately after removing the corresponding part will avoid confusion during assembly. If this is not possible, all fasteners should be placed in a box specially prepared for this purpose, divided into sections and appropriately labeled, or simply in separate labeled boxes. This course of action is especially useful when dealing with components that consist of many small parts, such as a carburetor, alternator, valve train, instrument panel, or trim elements.

When disconnecting electrical contacts and connectors, attention should be paid to marking wires or harnesses using adhesive tape with a digital or letter code applied to it.

Sealing surfaces

On all vehicles, gaskets are used to seal the junction of the mating surfaces of two or more parts and serve to prevent leakage of oils and fluids and maintain high pressure or vacuum inside the assembly.

Often such gaskets are coated with a liquid or paste sealing compound before installation (sealant). Often, under the influence of time, temperatures or pressure, such a strong "sticking" mating surfaces to each other, that the separation of parts becomes a difficult task. In many cases, the successful dismemberment of such nodes is helped by tapping the components from the outside along the perimeter of the joint with a soft-faced hammer. You can also use an ordinary hammer for this purpose, striking through a wooden or plastic spacer. Cast housings and fragile components should not be tapped. When this type of problem occurs, always check that all fasteners have been removed first.

Avoid prying the parts with a screwdriver or pry bar inserted into the joint area, as the sealing surfaces can easily be damaged, which will further lead to the development of leaks. If jerking "stuck" assembly elements cannot be avoided, use a pen from the old estimate for this purpose, but remember that after all the chips formed must be carefully removed both from the mating surfaces and from the inside of the assembly.

After separating the parts, their mating surfaces must be carefully cleaned, scraping off traces of the old gasket material. Hardened fragments can be pre-softened with a rust converter or a special chemical composition, and then removed from the mating surface with a scraper. In this case, a piece of copper tube with a flattened and pointed end can be used as a scraper. The use of copper tubing for this purpose is recommended, as copper is usually softer than materials used in automobiles, which reduces the risk of damage to the mating surface. Some gasket residue can easily be removed with a copper brush, however, regardless of the method used, the mating surfaces must be completely clean and dry. If for any reason the mating surface is damaged, fill the defects with gasket sealant before assembling the components. In most cases, you should use a non-curing (or partially frozen) sealant.

Hose Removal Tips

Attention! If your car is equipped with an air conditioning system, never disconnect any hoses from the system components until the path has been discharged by a Skoda authorized workshop or an air conditioning specialist.

The precautions to be taken when removing hoses are very similar to those for removing gaskets. Avoid damage to the surfaces of fittings and pipes on which the ends of the hoses are pulled, as this may cause the development of leaks. In particular, the latter applies to the procedure for removing the radiator hoses. Due to the various chemical reactions taking place in the tract of the cooling system, it often occurs "sticking" rubber hoses to the mating surfaces of fittings and branch pipes. To remove the hose, first of all, loosen the clamp securing it to the fitting. Then grab the hose near the clamp with tongs and begin to rotate it on the fitting / connecting pipe to the right and left. Continue the procedure until the hose is completely free, then remove the hose from the fitting. A small amount of silicone or other lubricant introduced into the gap between the fitting and the hose will make the job easier. Before installing the hose, lubricate the inner surface adjacent to the end, as well as the outer surface of the fitting with a solution of soapy water or a small amount of silicone grease.

As a last resort, or if it is absolutely necessary to replace the hose with a new one, the end of the hose put on the fitting can be cut with a knife and then separated from the surface of the fitting. At the same time, try not to damage the metal of the fitting / connecting pipe with a knife.

If the hose clamp is damaged, replace it with a new one. Twist-type clamps usually loosen over time, so regardless of condition, it is best to replace them with screw-type clamps on occasion.