Introduction

Mandatory regular vehicle maintenance procedures include a set of simple checks that take a minimum of time, but allow you to avoid unforeseen expenses for sometimes expensive repairs.

These checks should be carried out weekly and do not require any special skills and ability to use special tools from the performer.

- Monitor the condition and inflation pressure of tires - timely detection of defects will not only increase the life of the treads, but also avoid getting into an emergency.

- A large number of failures are associated with malfunctions of electrical equipment. The most typical are violations related to the state of the battery.

- Remember that the first sign of a brake fluid leak is a vehicle braking problem. Regular checking of the fluid level will help to avoid getting into an emergency.

- Be aware that damage due to lack of engine oil or coolant can require very expensive repairs. Check the levels of the mentioned fluids regularly. Try to detect leaks in time and eliminate their cause.

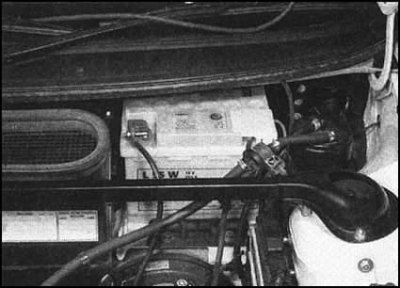

The illustrations show the main test points of the engine compartment of each of the Skoda Felicia models covered in this manual.

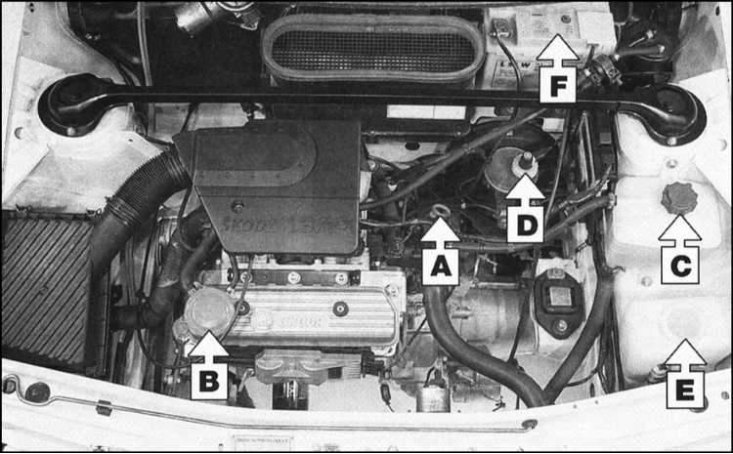

Petrol models 1.3 l

A - Engine oil dipstick; B - Engine oil filler cap; C - Expansion tank of the cooling system; D - Brake fluid reservoir; E - Windshield washer fluid reservoir; F-Battery

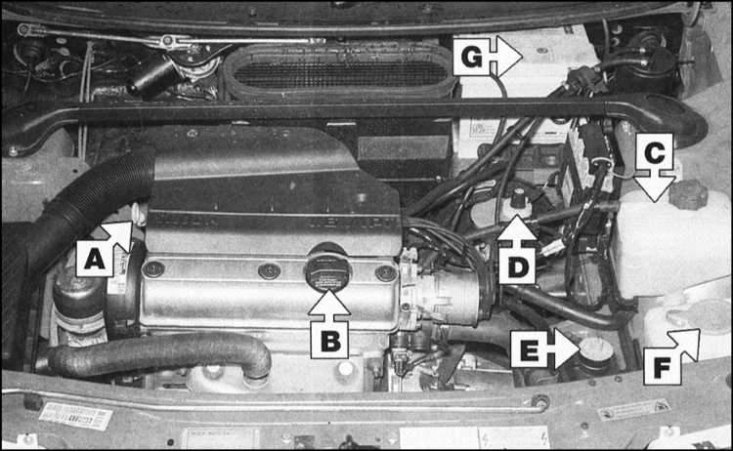

Petrol models 1.6 l

A - Engine oil dipstick; B - Engine oil filler cap; C - Expansion tank of the cooling system; D - Brake fluid reservoir; E - Fluid reservoir of the power steering system; F - Windshield washer fluid reservoir; G - Battery

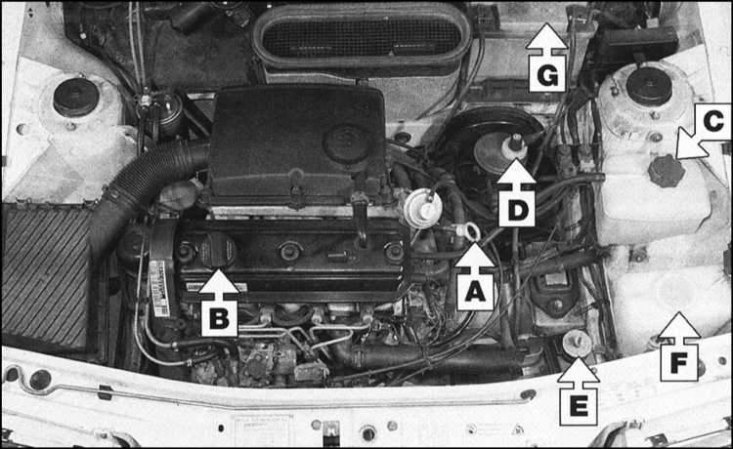

Diesel models 1.9 l

A - Engine oil dipstick; B - Engine oil filler cap; C - Expansion tank of the cooling system; D - Brake fluid reservoir; E - Fluid reservoir of the power steering system; F - Windshield washer fluid reservoir; G - Battery

Checking the engine oil level

Note. It is carried out before the trip, or after at least 5 minutes after turning off the engine. Otherwise, part of the oil will be distributed over the surface of the lubricated engine components and the test will give an underestimated result. The vehicle must be parked on a flat, level surface, if possible with a hard surface.

Modern cars are very sensitive to the choice of engine oil poured into the engine. Try to adhere to the recommendations given in the relevant Section of the Introduction to this Guide.

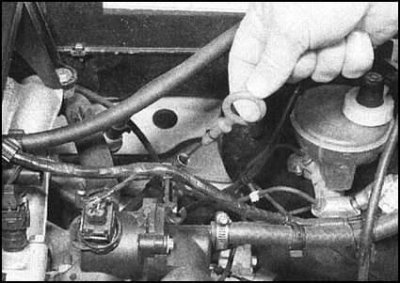

1. Remove the engine oil dipstick, the handle of which is usually brightly colored.

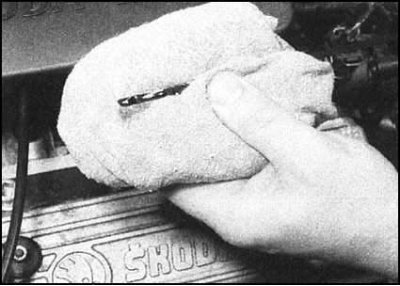

2. Wipe the stylus blade dry with a clean, lint-free cloth, insert the stylus back into the guide tube (all the way) and take it out again.

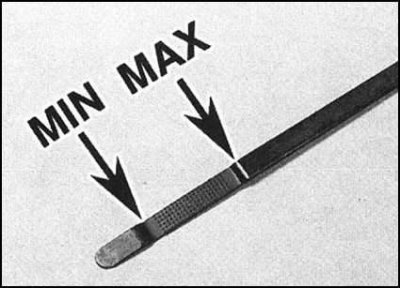

3. The oil level should be between the MIN and MAX marks on the dipstick blade. If the edge of the wetted area of the blade is near the MIN·mark, add an appropriate amount of engine oil of the same grade as the one already in the engine.

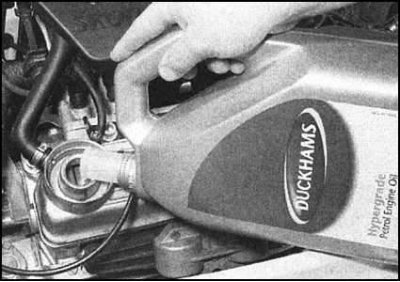

4. Oil is poured into the engine through a special neck, from which the cover must first be removed. Fill with oil in small portions, each time checking its level on the dipstick and maintaining pauses sufficient for the filled portion to drain into the oil pan. Continue the procedure until the oil level is between the marks on the dipstick blade.

5. If the need to adjust the engine oil level occurs too often, check the unit for signs of leaks. The easiest way to spot leaks is to leave a blank sheet of cardboard under a car parked overnight. If there are no leaks, burnt oil may be the cause of the oil consumption (see Section Diagnostics of malfunctions of components and systems of the car).

6. Try to keep the oil level between the marks on the dipstick blade (see above). Excessive level drops can damage internal engine components due to oil starvation. Exceeding the level norm usually leads to failure of the crankshaft oil seals.

Checking the coolant level

Note. To avoid steam burns, never remove the cap from the filler neck of the expansion tank when the engine is hot!

Remember that coolant is highly toxic - do not leave an open container with antifreeze!

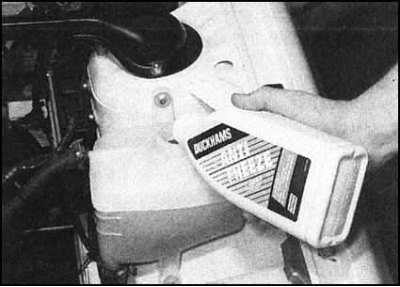

To prevent internal corrosion of components, the cooling system should be filled with an antifreeze/water mixture throughout the year, not just during the winter months. Try to prevent dilution of the coolant by using clean water to correct its level.

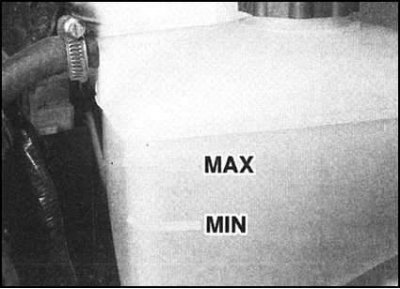

1. The fluid level in the expansion tank of the cooling system may vary depending on the temperature of the engine. The norm is to find the level between the MIN and MAX marks on the translucent wall of the tank when the engine is cold. As the engine warms up, the fluid level may rise slightly above the MAX mark.

2. If it is necessary to correct the coolant level, wait for the engine to cool completely. Slowly unscrew the reservoir cap to release any residual internal pressure in the system.

Note. To completely avoid the risk of scalding, it is better to wrap the lid with a rag before unscrewing it.

3. Add a properly formulated antifreeze/water mixture to the reservoir. Continue adding fluid until the level is between the MIN and MAX marks on the sides of the reservoir.

4. In the sealed type cooling systems typical of most modern cars, the need to adjust the coolant level arises only in the event of leaks. The most typical sources of leaks are the radiator housing, hoses and joints of mating components of the power unit. Try to eliminate the causes of detected leaks without delay.

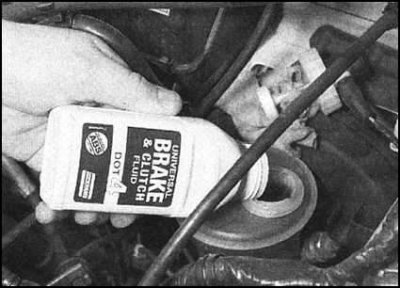

Checking the brake fluid level

Note. Remember that brake fluid is highly toxic and corrosive to paintwork - follow the appropriate precautions.

Brake fluid is also highly hygroscopic, i. has the ability to absorb moisture from the atmosphere. Do not use fluid that has been stored for a long time in a loosely closed container to adjust the level - the presence of moisture in it leads to a dangerous decrease in braking efficiency.

Note. As the brake pads wear, the fluid level in the GTZ reservoir drops slightly due to the gradual extension of the caliper pistons and wheel cylinders. However, the liquid level must not be allowed to fall below the MIN·mark on the tank wall.

1. A translucent brake fluid reservoir is located on the left bulkhead of the engine compartment. Liquid level marks are marked on the front wall of the tank.

2. The brake fluid level must be constantly maintained between the marks on the tank wall. Before making adjustments (if there is a need for such) Thoroughly wipe the reservoir filler cap and surrounding area to prevent dirt from entering the hydraulic system.

3. Unscrew the cap and carefully remove it from the reservoir neck. Try not to damage the float of the sensor-switch of the control lamp of the brake fluid level mounted in the cover. Place the float cap assembly on a clean piece of cardboard or lined with a rag, then carefully inspect the outside of the tank. If there are signs of brake fluid contamination, the hydraulic system should be emptied and filled with fresh fluid.

4. Carefully add fresh liquid from a freshly opened container to the reservoir. Be careful not to splash on the surfaces of nearby components and the paintwork of the body panels. Use only the correct grade of fluid to correct the level. Remember that mixing liquids of different grades is by no means permissible!

5. If the need to adjust the brake fluid level occurs too often, the hydraulic system should be checked for leaks, the causes of which should be eliminated without delay.

Attention! If a brake fluid leak is suspected, the vehicle should be refrained from operating until a thorough check of the system has been performed.

Checking the condition and inflation pressure of tires

It is extremely important to constantly keep the tires in good condition and inflated with the proper pressure - wheel failure while driving (at any speed) extremely dangerous. The wear rate of tire treads is primarily determined by the driving style - frequent sudden braking and acceleration, making turns without slowing down, etc. factors greatly contribute to the reduction of tire life. As a rule, the treads of the front wheels wear out somewhat earlier than the rear ones, so the timely rotation of the wheels of the car allows you to achieve more even tire wear and, as a result, extend their service life. However, it should be noted that with uniform wear of the protectors, the car owner is faced with the need to perform a one-time replacement of four wheels at once, which not every motorist can afford. In this case, it is better to neglect the rotation of the wheels and replace the tires in pairs, thereby spreading the waste.

Regularly inspect the treads of all wheels of the vehicle, removing small stones, nails and other foreign objects stuck in the grooves of the tread pattern before they cause a wheel puncture. If a puncture is detected when removing the nail, insert the nail back into the hole, marking the defect, then change the wheel and take it to a tire shop for repair.

Also pay attention to defects such as cracks, cuts, swelling ("eggs") and the like, which are most often formed on the side surface of the tire. Remove the wheels regularly to thoroughly clean the discs of dirt from both the outside and the inside. Check disc rims for signs of corrosion, deformation and other damage. Remember that discs made of light alloy easily fail when driving over curbs and deep coating defects. Stamped wheels in such situations are usually only deformed and can be restored by rolling on a special machine available in almost any tire shop. In case of severe damage, discs cannot be repaired and replacement becomes the only alternative.

Each time a tire is changed, the wheels must be balanced as a whole. The need to re-balance the wheels may arise in the process of wear of the treads, as well as in the event of loss of counterweights. Imbalance of the wheels leads to a reduction in the life of the protectors due to their accelerated wear. In addition, during driving, the vibration load on the suspension and steering components increases significantly. The first sign of wheel imbalance is the occurrence of noticeable vibrations, especially noticeable at certain speeds (typically around 80 km/h [50 mph]). If the vibration is transmitted mainly to the steering wheel, then only the front wheels are out of balance. In case of body vibration, all wheels of the car should be balanced. Wheel balancing should be carried out in a tire shop.

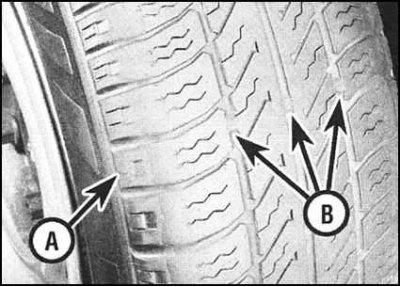

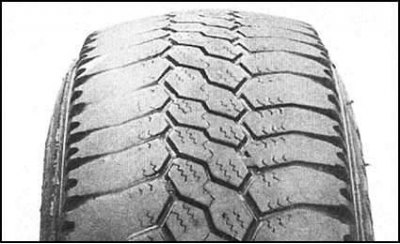

Visual check of tread wear

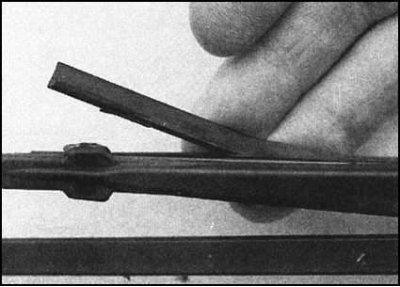

The wheels included as standard on Skoda Felicia vehicles are usually equipped with built-in tread wear indicators. Indicators are colored rubber strips (IN), mounted in the middle part of the tread and manifested when the latter is worn to a residual depth of the pattern below 1.6 mm. The location of the indicators on the tread is determined by triangular marks applied to the side surface of the tire (A).

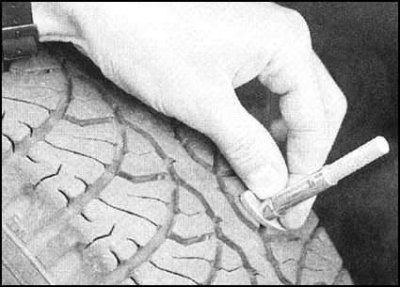

Measuring the residual tread depth manually

Alternatively, the degree of tread wear can be determined by measuring the remaining depth of the tread pattern using a feeler gauge, which is available relatively inexpensively from virtually any automotive accessory store.

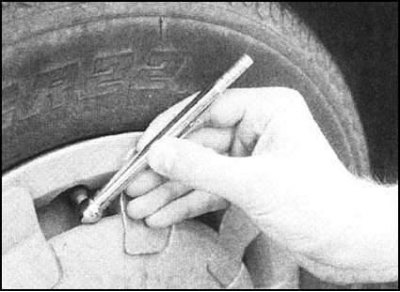

Checking tire inflation pressure

Tire inflation pressure should be checked regularly and with cold tires. Performing a pressure adjustment immediately after the end of a ride, when the wheel is still warm, will only lead to a violation of the required parameters.

Typical examples of tread wear

Shoulder wear

Uniform shoulder tread wear (the same on both sides) usually defined as excessive tire deflection as a result of too little tire inflation pressure and is accompanied by overheating of the tire, loss of grip and reduced wheel life, not to mention increased risk of tire blowout while driving. Check and correct tire inflation pressure.

One-sided shoulder wear of the tread is most often associated with a violation of the wheel alignment angles. The geometry of the suspension should be checked without delay and appropriate corrections made.

Another reason for shoulder tread wear is driving too hard - slow down when cornering!

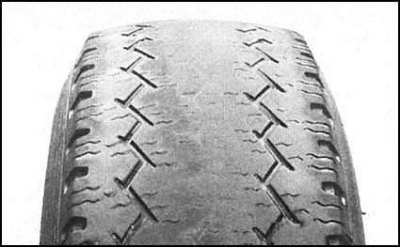

Central wear

Excessive tire inflation pressure leads to tighter contact with the road surface of the central part of the tread, which leads to faster operation of the latter. Among the side effects, it should be noted a decrease in the adhesion of the wheel to the road surface, an increase in the rigidity of the car, not to mention an increase in the risk of an unexpected rupture of the tire. Check and correct tire inflation pressure.

Sometimes a temporary increase in tire pressure is necessary, such as when carrying heavy loads, driving at high speeds for a long time, etc. Remember to depressurize your tires to normal when you return to normal driving conditions.

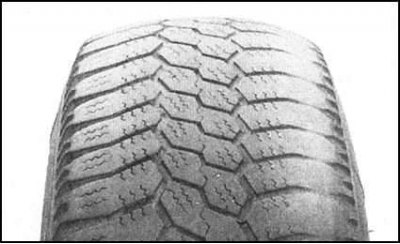

Uneven wear

Uneven wear of the treads of the tires of the front wheels may be associated with a violation of the installation angles of the latter. You can check and correct the geometry of the front suspension of a car for a relatively small fee in almost any tire shop.

In case of violation of the camber or run-out of the wheels, the necessary repair or replacement of the failed suspension components should be carried out.

Don't forget to check and properly adjust the wheel balance.

In case of violation of the convergence of the wheels, it is also necessary to make appropriate adjustments.

Note. Flaky tread wear, which usually accompanies misalignment, is most easily identified by touch.

Checking the windshield washer fluid level

Note. The tank located in the engine compartment is used for washing both the windshield and the rear windows of the car.

The addition of proprietary windshield wipers to the washer fluid not only makes it easier to clean the glass in rainy weather, but also increases the freezing point of the mixture. Do not add plain water to the windshield washer reservoir, as this thins the mixture and lowers its freezing point.

Attention! The use of antifreeze used in the engine cooling system as an additive to the glass washer fluid is fraught with damage to the paintwork of nearby body panels!

1. Windscreen washer fluid reservoir (and where required, and rear) glass is located on the left in front of the engine compartment.

2. The liquid level is checked through the translucent walls of the tank. If adjustments are needed, remove the reservoir cap.

Checking the fluid level of the power steering system (PAS)

Preparation

- Park the car on a flat, level surface, if possible with a hard surface.

- With the engine idling, turn the steering wheel slowly from lock to lock two or three times, then straighten it and stop the engine.

- Checking the hydraulic fluid level is done with the engine off. The system must be preheated to normal operating temperature.

Note. To ensure correct readings, do not turn the steering wheel after the engine has stopped.

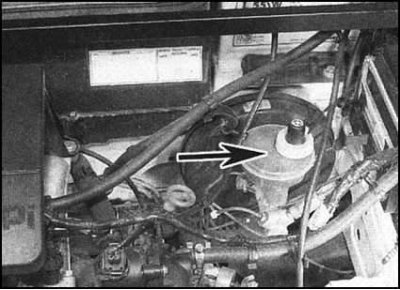

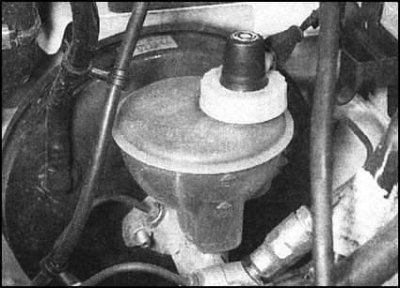

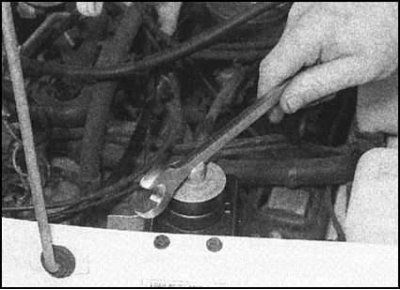

1. The PAS system reservoir is located on the left front of the vehicle's engine compartment. Thoroughly wipe the tank surface before removing the fill/inspection cap. The cover is unscrewed using a suitable tool tucked into a specially provided groove.

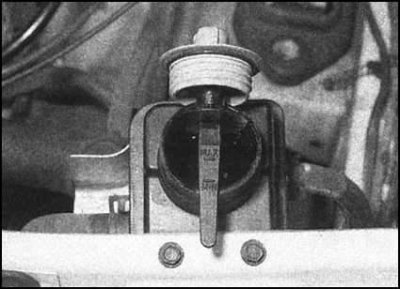

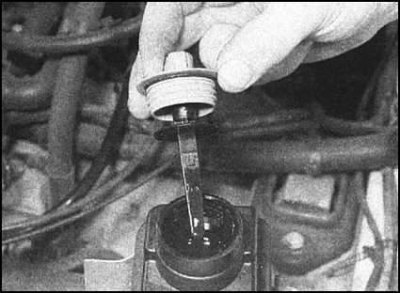

2. After unscrewing the cover, carefully wipe the blade of the probe mounted in it with a clean, lint-free rag. Replace the cover by hand-tightening it, then remove it again.

3. Determine the hydraulic fluid level from the wetted area of the dipstick blade. When the engine is cold, the fluid level should be near the MIN·mark, when it is hot, between the top (MAX) and lower (MIN) marks on the stylus blade. If necessary, add the appropriate amount of hydraulic fluid of the required grade to the reservoir. Finally, tighten the reservoir cap tightly.

4. The need for frequent regular topping up of PAS fluid indicates the presence of leaks in the system, the causes of which should be immediately identified and corrected.

Checking the condition of the wiper blades

Note. The following description of the procedure for replacing the brushes applies only to factory-equipped wipers on Skoda Felicia vehicles.

If replacing the brushes does not stop the smearing of dirt. You should try to simply wipe the glass with one of the special cleaners.

1. Check the condition of the rubber working elements of the brushes. If cracks, traces of aging of the material are detected, and if the brush does not clean the glass surface well, replace it. Replacement of brushes, regardless of the condition of their working elements, should be carried out annually.

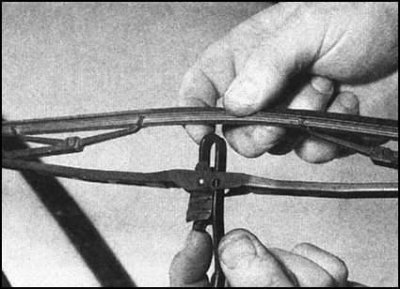

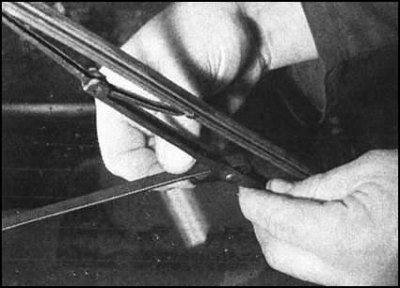

2. To replace the brush, move the lever away from the glass to its extreme position. Rotate the brush 90°, then depress the locking tab and remove the brush from the arm. When installing a new brush, make sure that it is securely fixed on the lever. Also make sure that the brush is positioned correctly on the glass.

3. Do not forget to check up a condition of a brush of a cleaner of back glass.

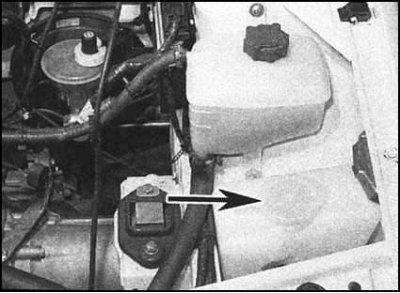

Checking the condition of the battery

Note. Remember to take special precautions when servicing the battery! Be aware of the dangers associated with the possibility of electric shock, creating a short circuit, contact with eyes, skin and painted surfaces of body panels with chemically aggressive electrolyte!

- Make sure the battery tray is in good condition. Check the reliability of fixing the battery on the pallet with a clamping bar. Traces of corrosion from the pallet, clamping bar and battery case can be removed with a baking soda solution. Upon completion, thoroughly rinse the treated surfaces with clean water. Corroded metal surfaces should be coated with a special zinc-based primer and then painted.

- Regularly (about once every three months) check the battery level.

- In the event of a low battery, the engine can be started from an external power source.

Note. The suspension of the development of corrosion of the terminals and terminal clamps is facilitated by treating them with acid-free petroleum jelly.

1. The battery is located at the rear of the vehicle's engine compartment. External inspection of the battery case for cracks and other damage should be carried out regularly.

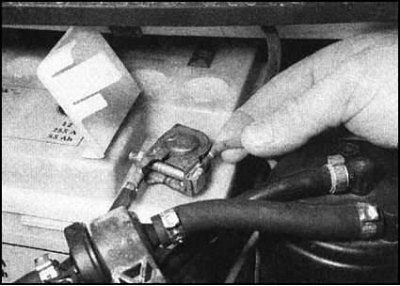

2. Check the tightness of the terminal clamps of the battery wires to ensure the reliability of the electrical contact. The clamps must not turn freely on the terminals. In parallel, check the condition of the wire insulation.

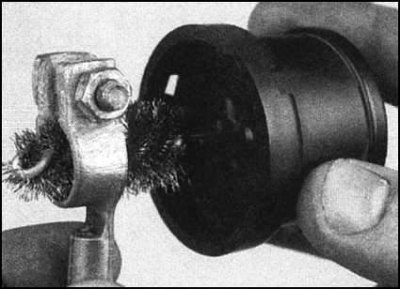

3. If there are signs of corrosion development on the terminals in the form of white powdery deposits, remove the clamps from the terminals and carefully clean the damaged surfaces with a stiff brush. Replace the clamps and tighten them firmly.

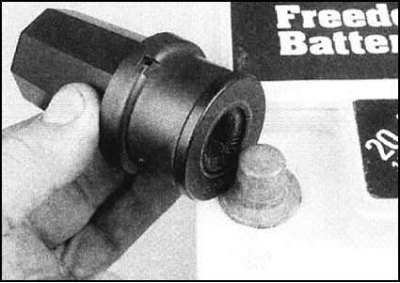

Note. Automotive accessory stores sell special tools for stripping battery terminals.

4. Special hard brushes are also available for cleaning the inside surfaces of the terminal clamps.

Checking the condition of lamps of lighting devices and fuses of electrical circuits

Check that all exterior lights and horn are working properly. In case of failures, check the condition of the electrical circuits (see the relevant Sections in Chapter Onboard electrical equipment).

Make a visual check of the accessible electrical wiring, its contact connections and intermediate clamps.

Note. In order to check the correct functioning of the brake lights and direction indicators alone, drive the car close to the garage wall and be guided by the reflections.

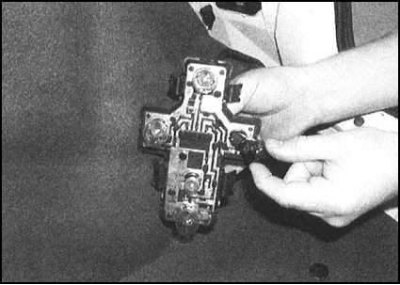

1. The failure of one of the brake lights or direction indicators is most often associated with the burnout of the corresponding lamp. See Chapter 12 for more information on replacing light bulbs. If both brake lights fail at the same time, it is most likely due to a sensor-switch failure (see chapter Brake system).

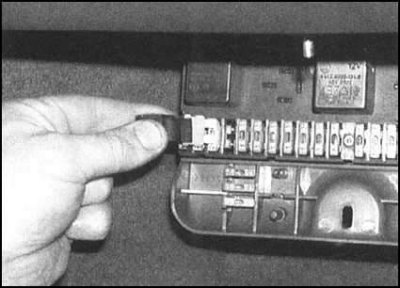

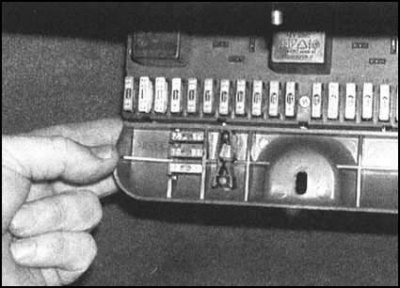

2. If more than one of the direction indicators or tail lights fails, check the condition of the corresponding fuse, as well as the wiring of the circuits protected by it (see chapter Onboard electrical equipment). The main part of the fuses is assembled in a mounting block equipped with a cover, installed under the dashboard of the car on its passenger side. Additional (built-in) fuses can be located directly on the protected component.

3. Using a special tool made of plastic and attached to the cover of the mounting block, remove the suspected fuse from its socket and carefully examine its condition. A blown fuse should be replaced with a fuse of the same amperage. Note that a simple fuse replacement is far from always enough to correct the situation - you should try to identify and eliminate the cause of the circuit overload (see chapter Onboard electrical equipment).