Front suspension and steering

1. Jack up the front of the car and place it on jack stands.

2. Perform a visual check of the condition of the anthers of the ball bearings and protective covers of the steering rack housing. Replace worn or leaking boots - dirt or moisture getting inside the boots will accelerate the wear of the ball joints and rack and pinion components.

3. On models equipped with power steering, check the condition of the PAS hoses. Inspect for signs of leaks nipple connections of hydraulic lines and covers of a case of a steering mechanism. Oil leakage through protective covers with increasing pressure inside the steering rack housing usually indicates wear on the oil seals.

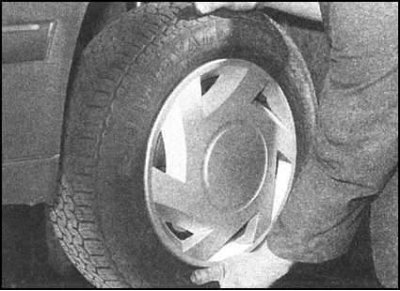

4. Grasp the front wheel of the car at the 12 and 6 o'clock points and pull it hard. The presence of the slightest noticeable backlash requires an investigation into the causes of its occurrence. While continuing to pull the wheel, ask the assistant to depress the foot brake pedal. If the play at the same time disappears or is noticeably reduced, then the wheel bearings are worn. Otherwise, the condition of the hinges and supports of the suspension components should be checked.

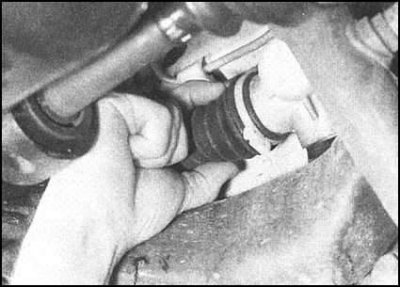

5. Now grab the wheel at the 9 and 3 o'clock points and repeat the test. Backlash again may be associated with wear on the wheel bearings. The second possible cause of slack is wear on the tie rod ends. When the outer tips are worn, there is usually a visual play of the wheel. To assess the degree of wear of the inner tip hinge, place your hand on the protective cover of the rack and pinion housing, grab the rod with the other hand. If you now pull the wheel, you can feel the play in the worn hinge.

6. Using a pry bar or a large screwdriver, assess the wear of the bushings of the suspension mounts: move the lever between the corresponding component and its anchor point. The presence of a small play is quite natural and is explained by the elasticity of the rubber inserts, however, excessive slack indicates wear on the support. In parallel, visually assess the condition of all exposed rubber pads and inserts. Pay attention to defects such as cracks, delaminations, tears, signs of aging of the material, etc.

7. Lower the vehicle to the ground and have an assistant turn the steering wheel approximately 1/8 turn to each side. Delay in the response of the steered wheels to the rotation of the steering wheel (backlash) should be very small, and ideally absent altogether. Otherwise check up a condition of hinges and supports of components of a suspension bracket and a steering drive. Assess the degree of wear of the cardan joints of the steering column, as well as the components of the actual rack and pinion.

Rear suspension

1. Chock the front wheels, then jack up the rear of the vehicle and place it on jack stands.

2. Acting as described above for the front suspension, evaluate the degree of wear of the wheel bearings, suspension bushings, and, if equipped, the strut shock absorber supports.

Suspension struts and shock absorbers

1. Check the shock absorbers for signs of hydraulic fluid leaks at the housing, rubber boot, and through the piston rod. Leaks indicate an internal defect in the shock absorber and the need for replacement.

Note. Replacing strut/damper assemblies is always done in pairs for a given suspension axle.

2. The effectiveness of the rack assemblies can be checked by pressing each corner of the car in turn. When the corner is released, the body should return to its original position without swinging. Otherwise, the corresponding shock absorber needs more detailed attention. Don't forget to also assess the wear on the upper and lower shock mount components.