1. Drive the car onto a flyover / viewing hole, or jack it up and place it on props. Make sure that the car raised above the ground is located strictly in a horizontal plane. The transmission oil level should be checked before the first trip of the day, or at least 5 minutes after the engine has been stopped. The results of a measurement taken immediately after stopping the vehicle cannot be considered reliable, since part of the oil will be distributed over the surfaces of the internal components of the gearbox.

2. Wipe the surface of the manual transmission housing from above, in the area where the speedometer drive is located.

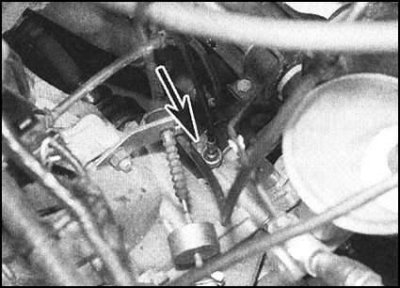

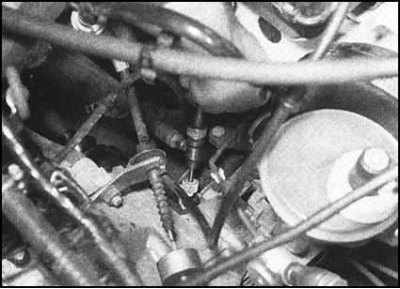

3. Turn out a bolt, remove a fixing plate,

then remove the speedometer drive assembly from the transmission case.

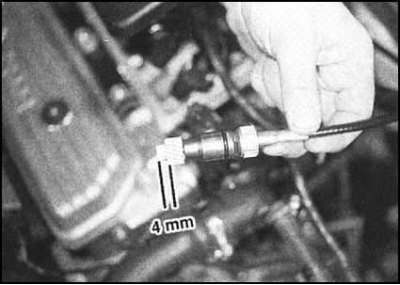

4. The transmission oil level is checked using the speedometer drive gear, which in this case is used as a dipstick. Wipe the gear dry with a clean, lint-free rag, then push the drive assembly into place in the transmission case until it stops. Remove the assembly again and determine the oil level in the crankcase by the length of the wetted part of the gear. The edge of the wetted area of the gear should be located 4 mm above the base of the latter. A slight excess of the oil level is allowed, however, in no case should it fall below the agreed point.

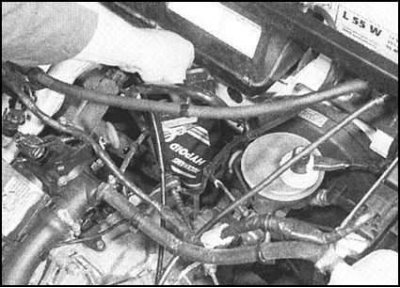

5. If the level is insufficient, make the appropriate adjustment by filling in the required grade of oil through the hole for the installation of the speedometer drive assembly.

6. Excess oil can be pumped out of the crankcase through the same hole using a syringe or rubber bulb.

7. Having finished adjusting the oil level, check the condition of the O-ring of the speedometer drive gear, replace the defective ring. Lubricate the new o-ring with clean transmission oil and seat the drive assembly in its original location in the transmission case. Insert the mounting plate into engagement with the groove of the gear, then screw in and tighten the mounting bolt to the required force.