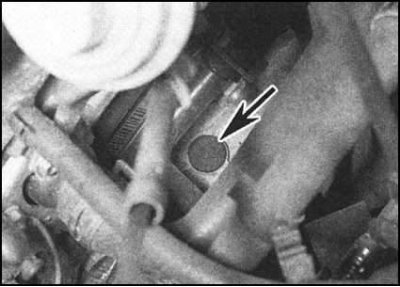

2. Remove the viewing window plug from the clutch dome...

... and turn the crankshaft clockwise with a key, achieving a position where the mark on the flywheel is in the middle of the viewing window opening.

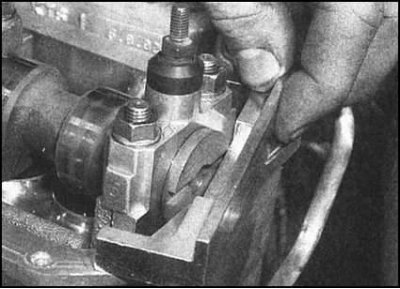

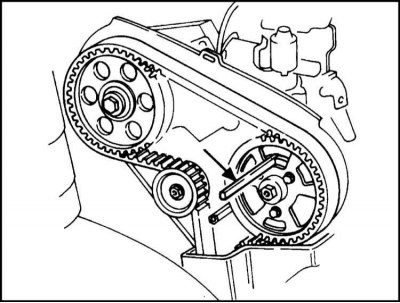

3. To fix the engine in the TDC position, block the camshaft (not his gear) and the gear wheel of the injection pump in the installation position using special tools. Despite the potential possibility of self-manufacturing of equivalent devices, the required measurement accuracy requires preference for branded blockers. The compilers of this Guide recommend Sykes Pickavant bollards currently on the market).

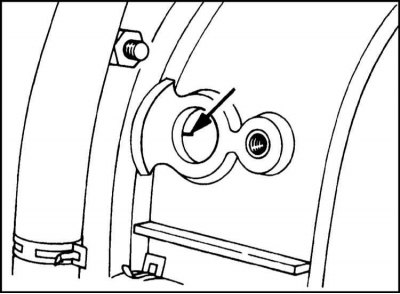

4. Enter the working edge of the blocker into engagement with the groove on the end face of the camshaft.

5. Without removing the lock, slightly turn the crankshaft clockwise (how did you do it before) so that the lock rests on the surface of the cylinder head. From the opposite end of the blocker, using a blade-type probe, measure the gap with the end face of the fixture and the head.

6. Slightly turn the camshaft in the opposite direction and remove the probe. Now it is necessary to align the blocker, putting two blades on both sides of it, the thickness of each of which should be equal to half the gap measured at the previous stage. Upon completion of the centering of the camshaft, the installation of the valve timing can be considered complete.

7. After passing a special locking pin into the mounting hole of the gear wheel of the injection pump and into the groove of the hub, fix the pump in the installation position.

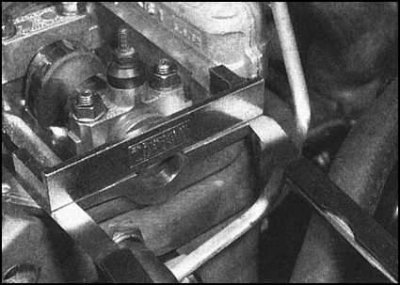

8. Now the engine will be brought to the TDC position of the end of the compression stroke of the piston of the first cylinder.