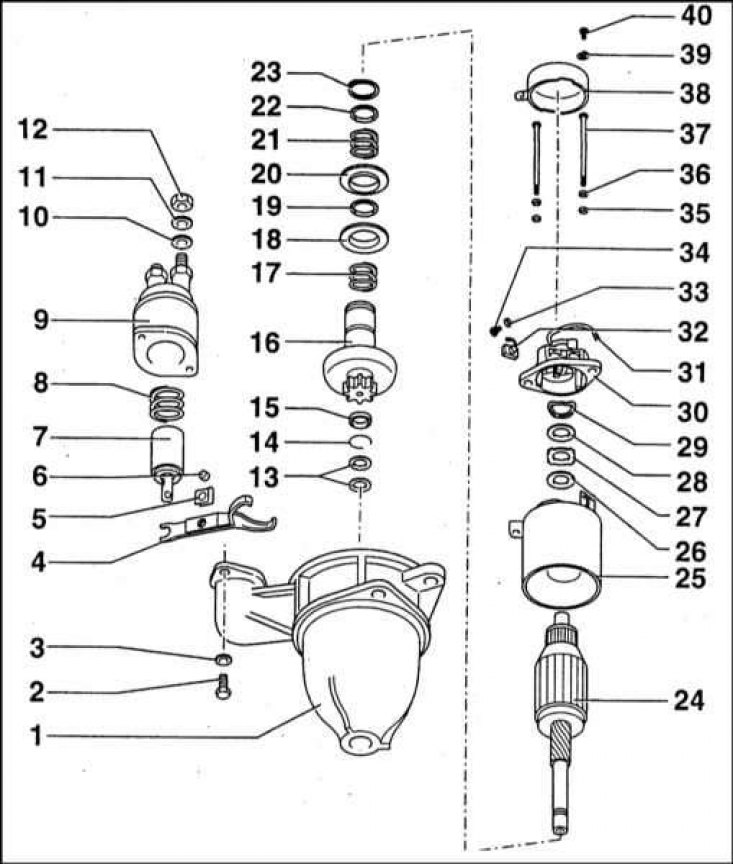

Magneton 1.0 starter elements

1 - Front cover; 2 - Mounting screw M6x16; 3 - Washer; 4 - Drive lever; 5 - Overlay; 6 - Pin; 7 - Anchor relay; 8 - Spring; 9 - Traction relay; 10 - Washer; 11 - Spring ring; 12 - Nut M10; 13 - Adjusting washer; 14 - Retaining ring; 15 - Retaining ring; 16 - Drive with overrunning clutch; 17 - Compression spring; 18 - Support washer; 19 - O-ring; 20 - Support washer; 21 - Compression spring; 22 - Washer; 23 - Retaining ring; 24 - Anchor; 25 - Housing with stator; 26 - Washer; 27 - Washer; 28 - Washer; 29 - Spring; 30 - Back cover; 31 - Connecting tape; 32 - Brush; 33 - Spring washer; 34 - Screw M4x6; 35 - Washer; 36 - Spring washer; 37 - Coupling bolt M6x123; 38 - Protective cover; 39 - Spring washer; 40 - Screw M6x10

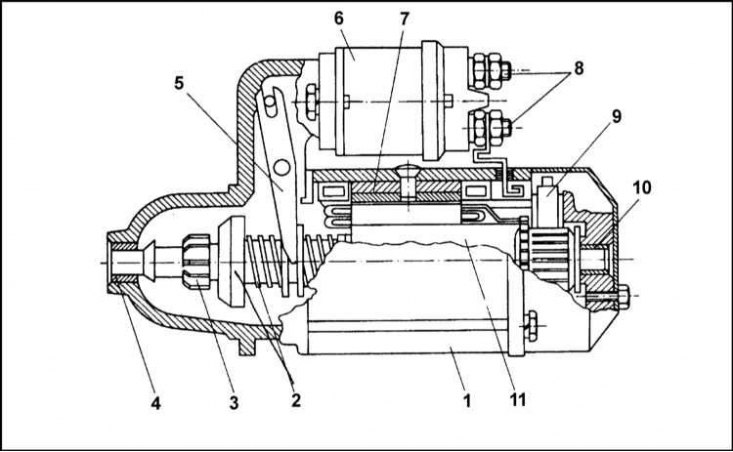

Magneton 1.0 starter section

1 - Housing; 2 - Overrunning clutch; 3 - Drive gear; 4 - Plain bearing; 5 - Lever; 6 - Traction relay; 7 - Stator; 8 - Main contacts; 9 - Brush; 10 - Plain bearing; 11 - Anchor

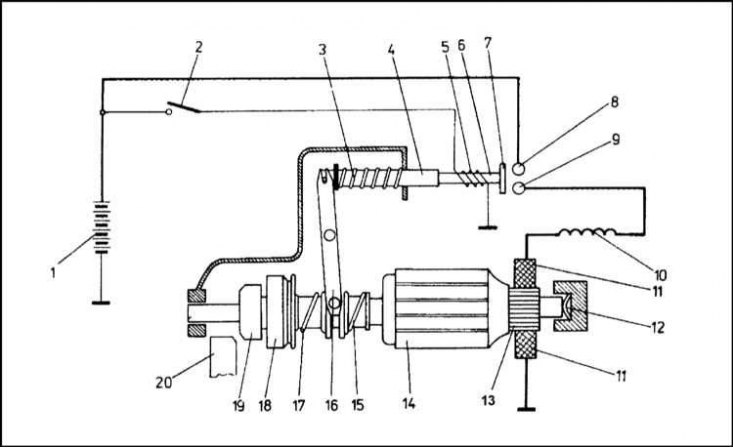

Starter switching circuit

1 - Battery; 2 - Ignition switch; 3 - Return spring; 4 - Plunger; 5 - Winding; 6 - Retractable rod; 7 - Contact pad; 8 - Main contact; 9 - Main contact; 10 - Excitation winding; 11 - Brushes; 12 - Brake washers; 13 - Collector; 14 - Anchor; 15 - Spring; 16 - Lever; 17 - Spring; 18 - Overrunning clutch; 19 - Drive gear

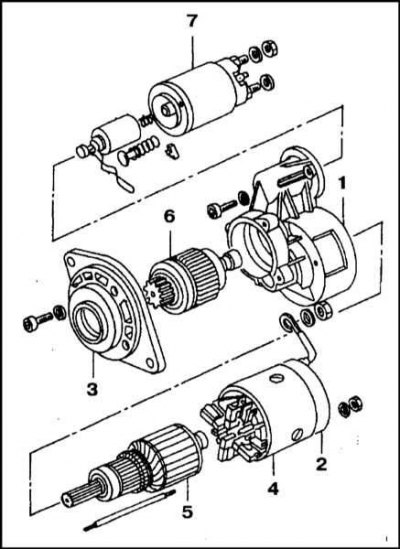

Starter Magneton 0.8 with planetary gear

1 - Housing; 2 - Back cover; 3 - Front cover; 4 - Stator; 5 - Anchor; 6 - Planetary gear; 7 - Traction relay

General information

The starter is a DC electric motor that turns the crankshaft through a reduction drive when the engine is started.

Until July 1995, all models were equipped with a 1 kW Magneton starter, from the aforementioned moment, a Magneton 0.8 starter was installed on the 1.3 liter model, which is characterized by smaller weight and size characteristics with increased torque. Both starters have the same mounting dimensions and are attached with two M8 bolts.

The starter is attached to the clutch dome. The starter drive gear is engaged with the flywheel ring gear by means of a traction relay.

The old type Magneton 1.0 starter consists of a housing, front and rear covers, anchor, overrunning clutch and traction relay. The starter housing is fastened to the front and rear covers with two through bolts.

Steel cores are fixed inside the case, on which excitation windings are wound. To enable the flow of large starting currents, the excitation windings are made of copper tape.

The armature consists of a shaft on which a core is pressed, consisting of separate magnetic plates isolated from each other. The plates have notches in the form of grooves. Rotor windings are laid inside the gutters. Both ends of the windings are brought to the collector.

The collector is located at one end of the armature shaft and consists of copper plates, also insulated from each other. The armature shaft ends with the journals of plain bearings, the bushings of which are planted in the body and the rear cover of the assembly.

On the opposite side of the shaft, spiral splines are provided, on which the overrunning clutch assembly with the drive gear is put on. When the traction relay is triggered, the gear moves along the splines of the shaft until it engages with the flywheel ring gear.

There are four brushes fixed in brush holders in the back cover of the case. The brushes are pressed against the commutator by a spiral spring. On the cover, with the help of an M6 bolt, a tin protective cover is fixed, which protects the collector and brushes from contamination.

The electromagnetic traction relay is mounted in the starter front cover assembly and fixed in it with two M6x16 bolts. The relay performs two functions: it drives the lever of the gear input mechanism into engagement with the flywheel crown, and also closes the feed circuit

The traction relay consists of a housing, inside of which the winding is located. A movable plunger made of a material with high magnetic permeability is inserted inside the winding. The plunger is connected to the starter drive lever. The plunger is returned to its original position using a special spring. A rod with a copper movable contact fixed on it is inserted into the plunger hole, closing the main contacts, which are the heads of two bolts directly connected to the battery terminals.

When the ignition key is turned to position II of the lock, the current from the battery begins to flow through the winding of the contact rod. The resulting magnetic field draws the plunger into the relay assembly. The movement from the plunger is transmitted to the lever fixed on it, which, in turn, shifts the drive assembly along the helical splines of the starter armature shaft towards the flywheel ring gear.

At the moment of closing the main contacts, current begins to flow through the starter winding and the drive gear engaged with the teeth of the flywheel crown spins the engine crankshaft. If the teeth of the gear and the crown at the initial moment were not engaged with each other, then such engagement will invariably occur under the influence of the force developed by the spring (17) at the moment of alignment of the gear teeth with the gap between the teeth of the flywheel crown.

Due to the fact that when the gear is engaged with the crown, it also has a translational motion, the initial jerk from the impact of the teeth is softened.

As soon as the engine starts and the flywheel speed exceeds the speed of the drive gear, the freewheel will begin to rotate freely on the armature shaft, thereby preventing the starter from being destroyed.

When the ignition key is released, the magnetic field of the coil of the contact rod disappears and the traction relay plunger returns to its original position under the influence of the force developed by the spring. In this case, the main contacts open and the starter power is turned off. The drive lever also returns to its original position and the gear disengages from the flywheel ring gear. Due to the helical shape of the guide pins on the armature shaft, the disengaged flywheel pushes the gear back. The drive lever compresses the spring slightly (15), which presses the armature assembly against the brake disc (12).

The new type Magneton 0.8 starter is equipped with a planetary gear. When turned on, the starter armature begins to rotate at a frequency of 5000 rpm, due to which a relatively large power is developed. In the planetary gearbox, the speed is reduced with a simultaneous increase in torque, which guarantees a trouble-free start of a cold engine even in frosty weather.

Removal and installation of starters of both types is carried out in a similar manner.

Removing

1. Disconnect the negative cable from the battery - this is especially important since the starter power cable is constantly energized.

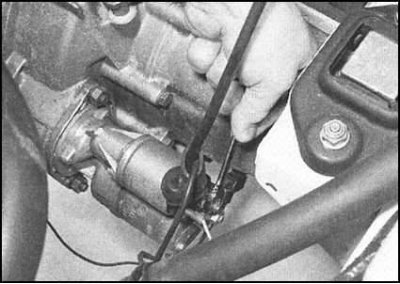

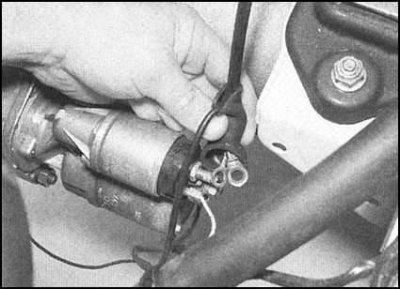

2. Remove a rubber protective cover and disconnect electroconducting from the back party of the traction relay. Try to remember the order of connecting the wires.

3. Release the latch, separate the electrical wiring of the reverse lights from the starter housing and take it to the side.

Note. It may be necessary to disconnect the reversing lights wiring from your sensor switch to ensure that there is no risk of damage to it during starter removal.

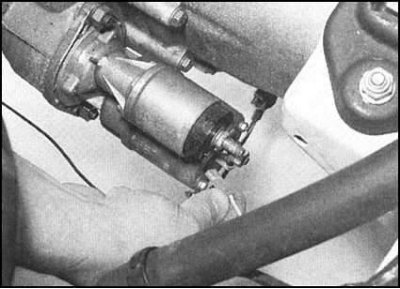

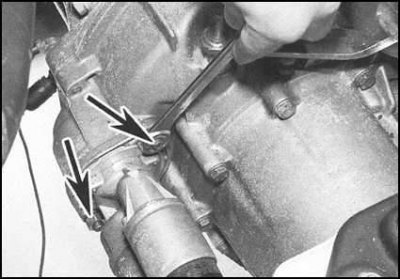

4. Supporting a starter a hand, give nuts of fastening on a dome of coupling.

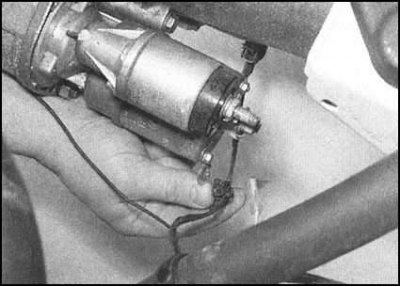

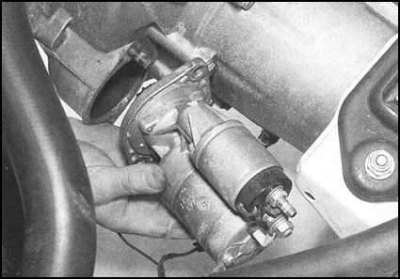

5. Remove the starter.

Installation

Installation is in the reverse order. Tighten all fasteners to the required torque. Make sure that the wiring is correctly laid and that the electrical wiring is connected securely.