General information

Note. The material presented in this subsection makes sense only if the distributor, explosive wires and timing belt are correctly installed.

The timing belt is put on the crankshaft and camshaft gears, which rotate in phase with each other. When removing the toothed timing belt during engine maintenance, it becomes possible to independently rotate each of the shafts, which inevitably leads to a violation of the valve timing.

The design of the engine under consideration does not exclude the potential for damage to the pistons and valves when they hit each other near the upper limit of the piston stroke due to the absence of recesses in the bottoms of the latter.

For the above reason, the correct installation of the valve timing is of particular importance and is achieved by setting the engine before installing the timing belt in a certain initial position, called the top dead center (TDC). After bringing the engine to the TDC position before putting on the timing belt, turning the crankshaft and camshaft individually is by no means permissible.

Note. The timing belt is also used to drive the water pump, however, linking its rotation to the rotation phases of the crankshaft and camshafts is not so important.

top dead center (TDC) is the highest point of the piston stroke in its cylinder. Generally speaking, in 4-stroke engines, during the rotation of the crankshaft, this position is reached by the piston twice: once at the end of the compression stroke and the second time at the end of the exhaust stroke. To adjust the valve timing and set the ignition timing, in the vast majority of cases, the TDC of the end of the compression stroke of the piston of the first cylinder is used. It is this position that is commonly called the TDC position of the engine (the numbering of cylinders from 1 to 4 is made in the direction from the timing belt to the flywheel).

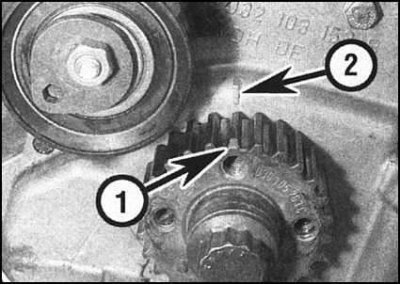

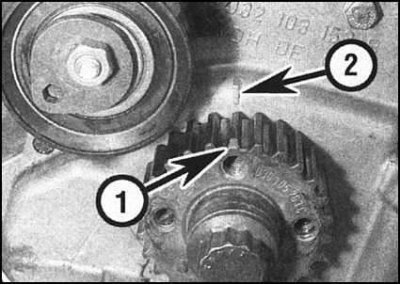

A groove is machined in one of the teeth of the gear wheel of the crankshaft, the alignment of which with the reciprocal mark on the gland flange confirms that the pistons of the first and fourth cylinders are brought to the TDC position. However, access to this gear is opened only after the lower cover of the timing belt is removed, therefore, a risk is additionally provided on the end surface of the shaft pulley, which in the considered situation (TDC of pistons of the 1st and 4th cylinders) aligns with the zero mark on the bottom cover of the belt. The camshaft gear is also equipped with an alignment dot mark, the combination of which with a convex pointer cast on the inner cover of the timing belt confirms that the engine is correctly brought to the TDC position when the piston of the first cylinder is at the top dead center of the end of the compression stroke.

6 Below is a description of the procedures for bringing the engine to the TDC position with and without the timing belt installed.

Bringing the engine to TDC with the timing belt installed

Disconnect the negative cable from the battery before starting the procedure.

Note. If your vehicle's stereo system is equipped with a security device, make sure you have the correct code to activate the audio system before disconnecting the battery.

De-energize the ignition system, to do this, disconnect the central explosive wire from the cover and, using a jumper wire, ground it to the ground of the cylinder block. Apply the parking brake and chock the rear wheels to prevent accidental movement of the vehicle. Make sure the manual transmission is in neutral.

Mark the position of the BB terminal of the wire of the first cylinder on the distributor cap relative to the body of the latter. On some models, such marking in the form of a special risk is already applied at the factory. Otherwise, trace the wire from the first cylinder to the distributor cap, then with a marker or paint (by no means with a slate pencil!) mark the edge of the distributor housing directly below the corresponding terminal.

Remove the distributor cap (see chapter Engine electrical equipment).

Disconnect the BB wires from the spark plugs. Try to remember the order in which they are connected.

To bring the piston of any of the cylinders to the TDC position, it is necessary to turn the crankshaft manually. Such turning is carried out using a socket wrench for the central bolt of the shaft gear (see Section Removing, checking the condition and installing gears and timing belt tensioner).

Turn the crankshaft in the normal direction (see Specifications at the beginning of the Chapter) so that the distributor slider turns with the nose of the electrode to the mark of the terminal BB of the wire of the spark plug of the first cylinder on the housing rim.

Note. Turning the crankshaft will be much easier if you first unscrew all the spark plugs.

Remove the top timing belt cover (see Section Removal and installation of the timing belt and its covers) in order to provide access to the camshaft gear located under it.

Locate the timing marks on the camshaft sprocket and the inner section of the belt cover. Continue turning the crankshaft clockwise until the marks are completely aligned.

Now find the alignment marks on the crankshaft pulley and the lower belt cover. On the cover there are raised marks in the form of the letters Z and 0. When the risk on the pulley rim is aligned with the zero mark, the engine will be brought to the TDC position.

Alternatively, make sure that the timing marks of the crankshaft gear and the flange of its front oil seal are correctly aligned.

Note. The crankshaft pulley and the lower belt cover must be removed in this case.

Make sure that the distributor slider is still turned with the tip of the electrode towards the mark of the first cylinder spark plug terminal on the rim of the assembly body. If it is not possible to achieve simultaneous alignment of the alignment marks of the shafts and the slider, you should check the correct installation of the distributor. (see chapter Engine electrical equipment).

After all the above conditions are met, the piston of the first cylinder of the engine can be considered brought to the TDC position of the end of the compression stroke.

Note. If it is now necessary to remove the timing belt, take care to securely lock the crankshaft and camshaft by their gears in order to prevent the engine from being pulled out of the TDC position.

Bringing the engine to the TDC position with the timing belt removed

The material in this subsection will help an amateur mechanic to return the engine to the TDC position in case of misalignment of the alignment marks with the timing belt removed during, for example, a major overhaul of the power unit.

Turning the camshaft with the timing belt removed and the crankshaft in TDC position can cause mechanical damage as a result of valve contact with the piston crowns. In view of the foregoing, the following procedure should be strictly followed.

Before installing the cylinder head on the engine, turn the crankshaft in the normal direction by the central bolt of its gear wheel, bringing the pistons of all cylinders to the middle part of their stroke. Moreover, the piston of the first cylinder should be fixed on the course of the compression stroke, approximately 90°before TDC.

After installing the cylinder head and camshaft sprocket, locate the alignment marks on the sprocket and the inner section of the timing belt cover.

Having turned the camshaft gear in the normal direction, achieve the alignment of the mentioned marks.

Now find the marks on the crankshaft gear and the flange of its front oil seal. Now rotate the crankshaft at the center wheel bolt in the normal direction by approximately 90° (quarter turn) and get the labels aligned.

Now find the marks on the crankshaft gear and the flange of its front oil seal. Now rotate the crankshaft at the center wheel bolt in the normal direction by approximately 90° (quarter turn) and achieve the alignment of the marks check the correct installation of the distributor (see chapter Engine electrical equipment).

After all the above conditions are met, the piston of the first cylinder of the engine can be considered brought to the TDC position of the end of the compression stroke.

Note. Before installing the timing belt, take care to securely block the crankshaft and camshaft by their gears in order to prevent the engine from being pulled out of the TDC position.