Examination

1. Jack up the front of the car and place it on jack stands.

2. Check the rubber pads of the supports for cracks, signs of hardening, delamination of rubber from the metal base and other mechanical damage. If such defects are found, the defective support must be replaced.

3. Using a torque wrench, check the correct tightening torque of the threaded connections of the supports.

4. Using a large screwdriver or pry bar as a lever, assess the degree of wear of the supports (if possible, use the help of an assistant, asking him to shake the power unit from side to side). If excessive play is detected, the worn support should be replaced after checking the reliability of tightening its fasteners.

Replacement

Right support

1. Disconnect the negative cable from the battery.

2. Hang the engine with a winch, or by supporting it with a jack (a block of wood should be placed between the jack head and the sump to distribute the load).

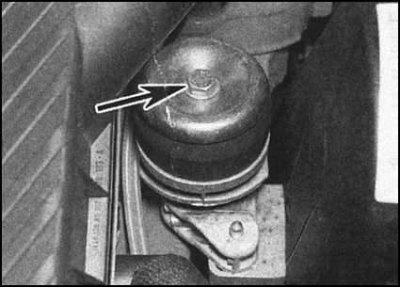

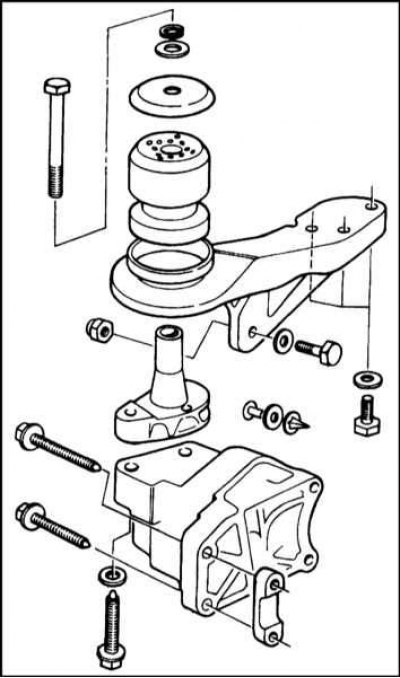

3. Turn out the top coupling bolt and disconnect a support...

... Trying to remember the installation position of the components to be removed, remove the rubber cushion from the assembly.

4. Now the remaining bolts can be removed and the support itself removed from the wheel arch mudguard.

5. If necessary, the lower part of the support can be separated from the engine block after first removing the timing belt covers (see Section Removal and installation of the timing belt and its covers).

6. Installation is carried out in the reverse order. Remember to replace the mounting bolts and lightly lubricate them with machine oil before installing. Tighten all fasteners to the required torque.

Left support

See Section Checking the condition and replacing the rubber pads of the suspension mounts of the power unit.

Rear support

See Section Checking the condition and replacing the rubber pads of the suspension mounts of the power unit.