Removing

1. Remove the rocker shaft assembly.

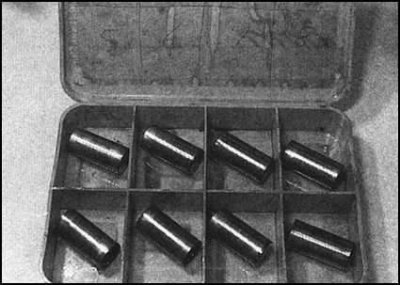

2. Remove the push rods one by one and put them in the order of installation on the engine in a box specially prepared and divided into sections. Please note that the intake valve push rods are made of aluminum, and the exhaust valves are cast iron.

3. Give four nuts of fastening of a cover of pushers to the forward party of the block of cylinders. Remove the washers and sealing bushings from the studs. Carefully pry the cover off the block and remove it together with the rubber seal.

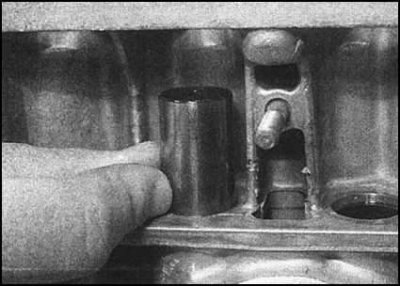

4. Remove pushers...

...and put them each to your bar. Remove pushrods and store in the order they were originally installed. Installation of usable components on the engine must be carried out strictly in the same order in order to minimize the wear rate of the camshaft lobes.

5. Remove the timing chain and sprockets.

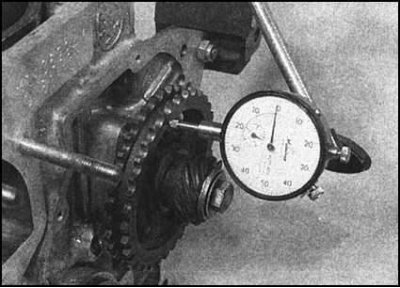

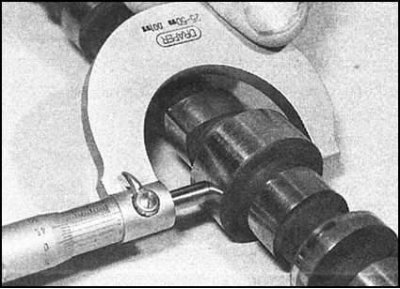

6. Before removing the camshaft, evaluate the amount of its axial play, for which purpose temporarily install the distributor / oil pump drive gear, cup and lock washers and screw the bolt into the end of the shaft pin, tightening it with the required force. Now, using a plunger-type dial gauge, evaluate the axial play of the shaft by measuring the amount of its free play in the longitudinal direction.

7. If the measurement result exceeds the specified Specifications permissible value, during assembly, replace the thrust plate of the shaft.

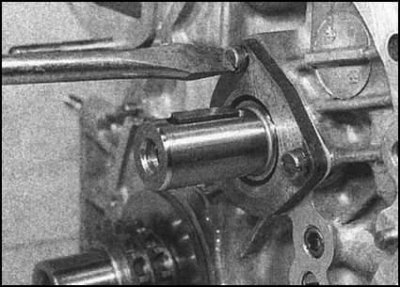

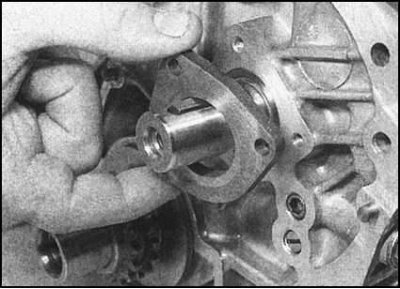

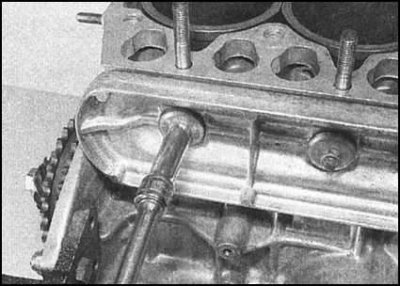

8. Remove the components temporarily installed to check the axial play, then unscrew the three screws securing the camshaft thrust plate to the cylinder block...

... Remove the plate...

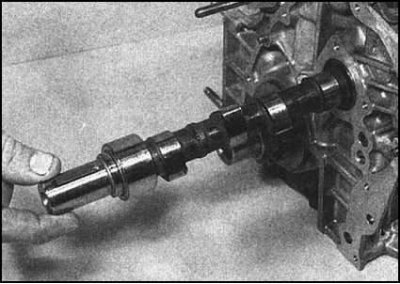

...and remove the shaft from the block.

Examination

1. Assess the degree of wear of the working surfaces of the pushers in contact with the camshaft cams.

2. Putting each of the pushers into its seat in the block, check the freedom of their landing. The pushers should move smoothly along their axis, but not have excessive lateral play.

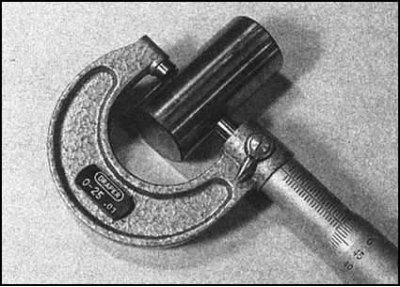

3. If the necessary equipment is available, the fit clearance of the pushers in the sockets can be determined by direct measurements.

4. Excessively worn (compare measurement results with requirements Specifications), or damaged pushers must be replaced.

5. If the pushers fit excessively loose in the sockets, or if signs of wear of the latter are found above the permissible limit, the block should be given to the groove, and the pushers should be replaced with new ones, repair size (in excess).

6. Check up a condition of cams and necks of a camshaft. In case of detection of defects in the surface of the necks, also evaluate the condition of the corresponding bearings in the body of the block.

7. If you have the necessary equipment, measure the diameters of the shaft journals, as well as the diameters of the bearings in the block. By subtracting the results of the first measurement from the last, determine the operating clearances in the bearings and compare the results with the requirements Specifications.

8. If there are signs of serious wear of the journals or cams, the shaft must be replaced. When the bearings are worn (compare the results of measuring their diameters with those specified in Specifications), you should consider the possibility of turning the block with the subsequent replacement of the liners with repair ones. If the groove is not possible, the block will have to be replaced.

9. Check up a condition of a persistent plate of a camshaft. If there are signs of wear, replace the plate.

Installation

1. Having generously lubricated the necks and cams of the valve drive with engine oil, fill the camshaft into the cylinder block.

2. Put the thrust plate on the shaft pin and fix it to the cylinder block with three screws. Repeat the shaft end play check. Install the thrust washer and check the end play.

3. Reinstall the timing chain and sprockets.

4. Lubricate the outer surfaces of the pushers with oil and fill the latter each into its seat in the block.

5. Check up a condition of a rubber sealing lining of a cover of pushers. In the absence of defects, the old gasket is subject to further use.

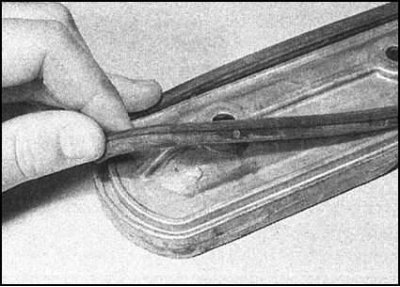

6. Thoroughly wipe the mating surfaces of the block and cover, then carefully insert the gasket into the groove on the inside of the cover.

7. Install the cover on the block - be careful not to dislodge or twist the gasket.

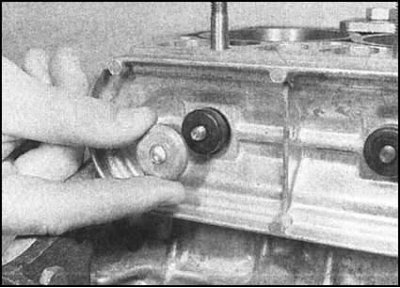

8. Put sealing sleeves and washers on the studs,...

... then screw on the nuts and tighten them to the required torque.

9. Install the push rods in their original positions. Follow the correct placement in your pushers.

10. Install rocker axle assembly, adjust valve clearances (see chapter Current service), then reinstall the cylinder head cover.