Removing

Note. Dismantling of the engine from the car is possible only complete with transmission. The dismemberment of the power unit for the purpose of overhauling the engine can be done later on a workbench or assembly stand. The assembly of the unit is lowered from the engine compartment down and then removed from under the car. Take care to ensure that there is enough free space under the car and that it is securely fixed in the raised position (see Section Removing the power unit from the vehicle - preparation and precautions, general information about the suspension of the power unit).

1. Park the vehicle on a level, hard paved area in such a way that there is enough free space around. Remove the hood (see chapter The procedure for assembling the engine after a major overhaul).

2. If the engine will be disassembled, drain the engine oil and remove the oil filter. Strip, screw in place and firmly tighten the drain plug of the oil pan.

3. Chock the rear wheels and firmly apply the parking brake. Jack up the front of the car, raising it to a height sufficient to dismantle the power unit. Support the raised vehicle securely on sturdy stands. Remove both front wheels.

4. Drain the gear oil, then carefully clean, screw in place and tighten the drain plug.

5. Empty the cooling system.

6. Loosen the intake pipe of the exhaust system and disconnect it from the exhaust manifold flange. On petrol models "take a walk" on the wiring from the l-probe to the connector and disconnect the sensor. Release the connector from the support bracket.

7. In accordance with the instructions given in Chapter Transmission, disconnect the gear selection rod and the shift bar from the manual transmission.

8. Remove the air cleaner (or only the air intake sleeve) - see the relevant Part of the Chapter Supply system. On petrol models 1.3 l and 1.6 l equipped with a multipoint injection system (MPFI), remove the throttle body cover.

9. Disconnect the storage battery and remove the generator.

10. Turn the clutch adjusting nut counterclockwise to loosen the cable as much as possible. Release the cable core from the clutch release lever and the sheath from its support bracket. Loosen the cable support bracket and remove it together with the ground bar (if the latter is provided).

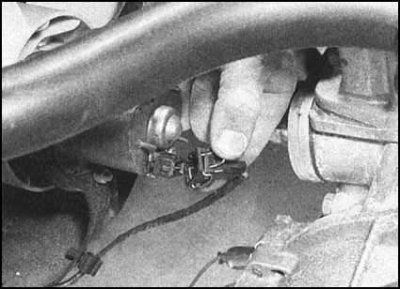

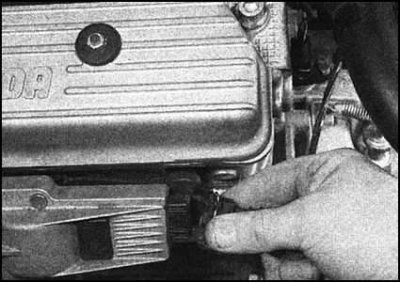

11. Loosen the knurled mounting nut, then pull up the speedometer drive cable to disengage the drive from the rear of the transmission. Alternatively, remove the mounting plate bolt and remove the drive gear from the box.

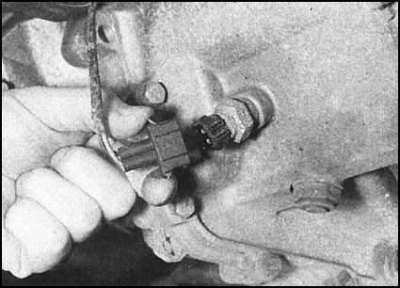

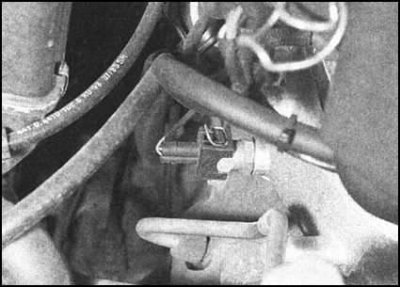

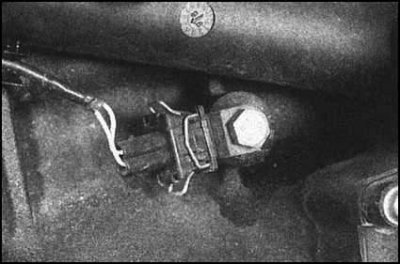

12. Disconnect the electrical wiring from the reversing lights switch located below the front of the manual transmission housing. If equipped, release the sensor-switch wiring from the retainer on the starter assembly.

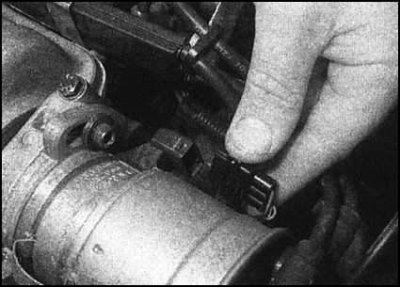

13. Slide the rubber protective cover back from the main terminal of the starter traction relay, then release the nut and disconnect the wire coming from the battery from the terminal. Carefully disconnect the bayonet connector of the traction relay.

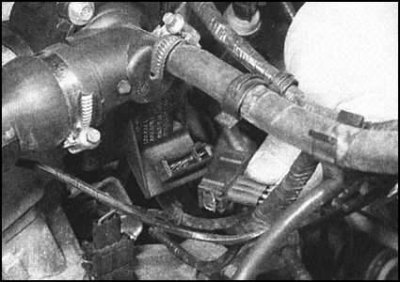

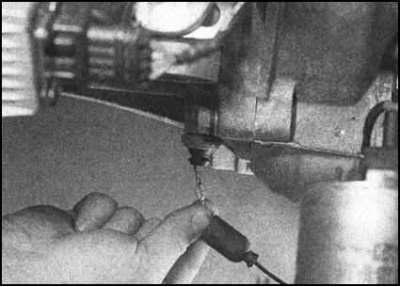

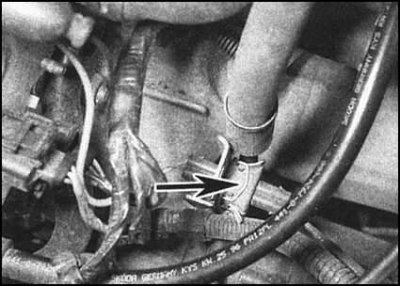

14. Disconnect the electrical wiring from the oil pressure switch. On petrol models, the sensor-switch is located on the bottom of the front wall of the cylinder block (1.3L models, either at the rear of the cylinder head (models 1.6 l), on diesel models - on the left side of the head.

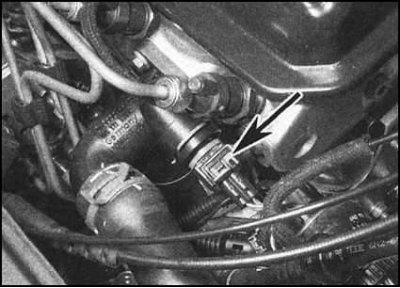

15. Disconnect the wiring from the coolant temperature sensor (CTS), located on the thermostat housing, or on the elbow of the cooling path (the sensor is installed on the pipe),...

...and also from the sensor-switch...

...and a cooling fan motor.

16. On models with power steering or K / V, remove the auxiliary drive belt.

17. On A/C equipped models, perform the following procedures:

- a) Disconnect the hose from the vacuum receiver;

- b) Disconnect the electrical wiring from the K / V compressor;

- c) Unbolt the compressor from the engine, take it to the side and tie it tightly. Try not to allow tension on the hoses of the refrigeration lines.

18. On models with power steering, remove the steering pump (see chapter Suspension and steering). There is no need to disconnect the hydraulic lines, just enough not to subject them to excessive stress when the pump is displaced. The pump must be installed in such a way that the lines cannot be damaged during the removal of the power unit.

Petrol models

1. On 1.3L models with central injection (SPFI) Disconnect the following communication lines from the intake manifold/throttle body:

- a) Fuel supply and return hoses;

- b) Throttle body wiring (release the bandages, release the tourniquet from the intermediate clamps and take it aside);

- c) Throttle cable (throttle cable);

- d) Hose of the vacuum amplifier of brakes;

- e) Coolant hoses;

- f) Purge hose for carbon adsorber;

- g) CTS wiring.

2. On models 1.3 l and 1.6 l with multipoint injection (MPFI) disconnect:

- a) Fuel supply and return hoses from the fuel pressure regulator;

- b) Vacuum hose from the fuel pressure regulator;

- c) Power system wiring (release the bandages, release the harnesses from the intermediate clamps and take them aside);

- d) Intake air temperature/pressure sensor wiring;

- e) On models 1.3 l - the electrical wiring of the ignition coil unit;

- f) Purge hose for carbon adsorber;

- g) Hose of the vacuum amplifier of brakes from the inlet pipeline;

- h) Knock sensor wiring on the back of the engine block.

- i) On models equipped with A/C, unbolt the compressor and move it away from the engine, without disconnecting any refrigeration lines in any case.

- j) Release the hoses / tubes of the refrigeration path from the intermediate clamps and also take them away from the engine.

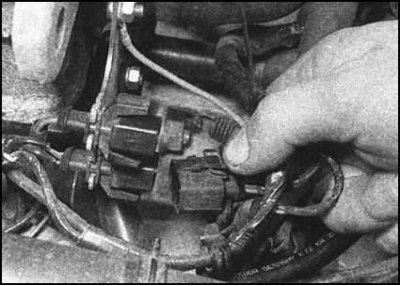

3. Disconnect the Hall sensor wiring. On 1.3L models, the 3-pin electrical connector is installed either in a bracket attached to the thermostat housing or on top of the transmission case. On 1.6L models, the sensor wiring connector is located on the ignition distributor.

4. If you have not done this before, disconnect the electrical wiring from the ignition coil.

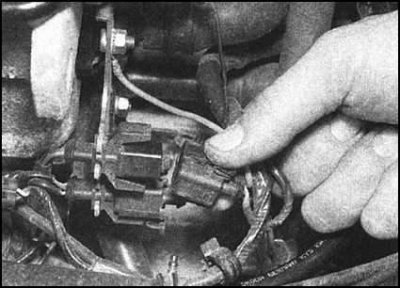

5. Remove the distributor cap, slider and protective screen.

Diesel models

1. Disconnect the brake booster servo hose from the vacuum pump (see chapter Brake system).

2. Disconnect the vacuum hose from the EGR valve (see chapter Supply system).

3. Perform the following procedures as needed (see part Diesel engine power system Heads of Power Systems):

- a) Release and turn out hollow bolts of union connections, then disconnect hoses of giving and return of fuel from TNVD;

- b) Release the mounting clamp and disconnect the injector bleed hose from the port on the fuel return fitting;

- c) Release the clamps and remove the intake air hose from the intake manifold cover;

- d) Disconnect the gas cable from the injection pump;

- e) Disconnect the wiring from the EGR and idle speed stabilization valves at the rear of the engine compartment. Try to remember the installation position of the connectors;

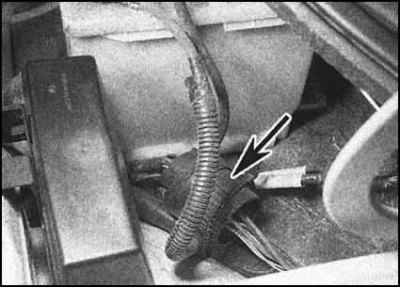

- f) Disconnect the multi-pin connector of the wiring harness, located under the upper support of the left front suspension strut; The connector has a threaded fit and the cover must be rotated to disconnect it. After breaking apart the joint, remove the inner seal. Pay attention to the presence of a red guide marking that determines the order of the connector's mating. To prevent moisture and dirt from getting inside the connector, wrap both halves of the connector in plastic wrap;

- g) Disconnect the two electrical connectors located in the bracket on the left side of the engine. Also disconnect the ground wire located just above. Wrap the halves of the disconnected connectors in plastic wrap;

- h) Where required, disconnect the alternator harness connector.

All models

1. Following the instructions given in the Chapters Engine electrical equipment and Supply system, identify the sections of wiring for the engine electrical, ignition and power systems that remain connected to the sensors and actuators on the power unit block. Disconnect all the remaining connectors that interfere with the dismantling of the power unit, first carefully marking them for correct mating during assembly.

2. Depending on the model, the power package may be equipped with one or more ground bars. tires are usually mounted either on the gearbox housing, near the right support of the unit, or at the base of the guide tube of the dipstick for measuring the level of impellent oil. Disconnect all tires.

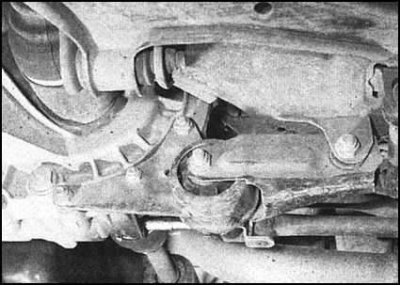

3. Remove the drive shafts from the transmission differential. To avoid damage to the CV joints, immediately tie the released ends of the shafts with wire to the suspension elements.

4. Hang the power unit with a winch or beam, completely removing its weight from the supports, but without violating the horizontal position. Since the unit is removed from the engine compartment through the lower opening, it would be unreasonable to support it from below.

5. To prevent damage to the oil pan, place an old floor mat, plywood, or just a sheet of cardboard under the engine compartment. After lowering, the unit must be moved forward, passing under the bumper in order to finally remove it from under the car, so it will be very handy to have a trolley jack at hand.

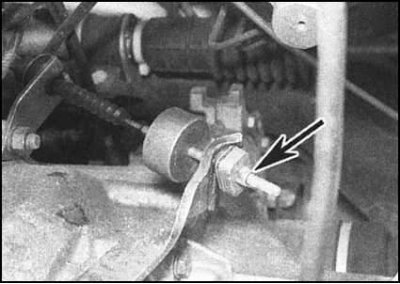

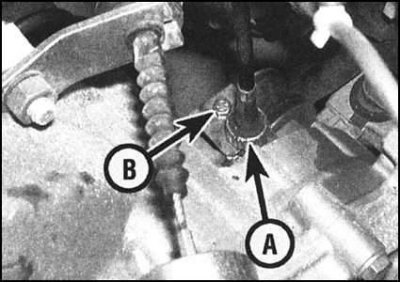

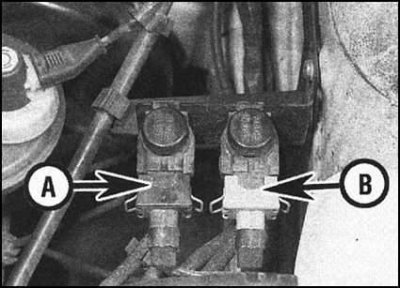

6. Turn out a through bolt of a back support of the power unit - Part A or B of the present Chapter see.

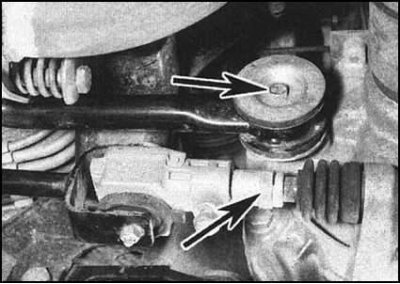

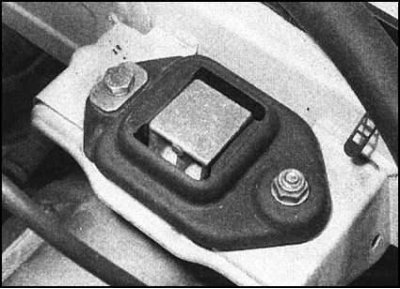

7. Mark the installation position of the left gearbox support. Give a self-locking nut, two bolts and remove a support plate from the top part of a pillow.

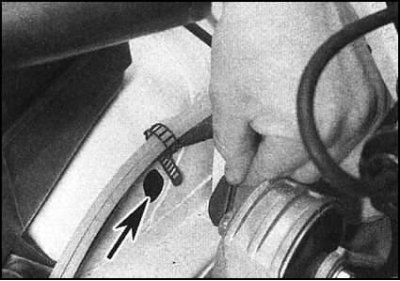

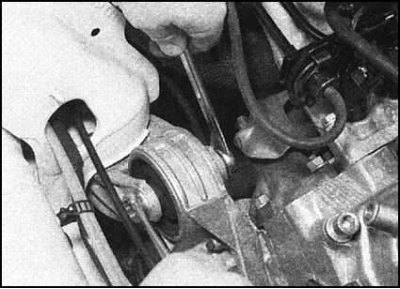

8. On 1.3L models, remove the rubber plug from the right mudguard,

thus providing access to the through bolt of the right support. Loosen the nut and remove the bolt.

9. On diesel models and 1.6 l models, turn out the two bolts of the right support from below, directly above the crankshaft pulley. Remove washers.

10. Make sure that no communications interfere with the removal of the power unit, enlist the help of an assistant and begin to carefully remove the assembly from the engine compartment, being careful not to cling to surrounding components such as the downpipe of the exhaust system or (with appropriate equipment) fittings of the hydraulic power steering system. With the unit lowered to the floor/cart jack platform, carefully remove the assembly from under the vehicle.

11. Immediately transfer the power unit to an assembly stand or a sturdy workbench where it will be disassembled and overhauled.

Transmission compartment

1. Take care of the reliability of fixing the unit on the stand / work surface (in the latter case, pre-prepared wooden beams and wedges should be used)

2. Remove the starter (see chapter Engine electrical equipment).

3. With the appropriate equipment, give the mounting bots and remove the flywheel cover plate from the gearbox housing.

4. Give fasteners (nuts/bolts) securing the gearbox housing to the engine block. Note that one of the bolts is used to attach the support bracket to the previously removed clutch cable. Being careful not to tilt, separate the gearbox from the engine by carefully removing it from the guide pins. Loosely seated pins are removed and stored in a safe place.

5. If necessary, remove the clutch release mechanism, basket assembly and friction disc (see chapter Clutch).

Installation

1. If the unit has not been dismembered, go directly to the material in paragraph 4.

2. Lightly lubricate the splines of the input shaft of the manual transmission with refractory grease (do not be too zealous to avoid the risk of contamination of the clutch friction disc). Gently press the box against the engine block, making sure the drive pins fit into the mating holes.

3. Install the mounting bolts/nuts and hand-tighten them.

Attention! In no case should you use fasteners for forced coupling of the box with the engine! Make sure that the mating surfaces of the clutch dome and the engine block are pressed against each other tightly and uniformly, only after that proceed with tightening the fasteners with the required force. Don't forget that one of the bolts is used to attach the clutch cable support bracket.

4. If equipped, reinstall the flywheel cover plate and secure it with bolts.

5. Get the assembly of the power unit under the front of the car.

6. Connect lifting rigging to the lifting eyes of the block and hang the assembly above the ground

7. With the help of an assistant, drive the unit into the engine compartment of the car, ensuring the possibility of connecting the right support. Tighten the fixing bolts (or through bolt with nut) with the required effort. On 1.3L models, install a rubber plug into the right mudguard access hole.

8. Connect the left transmission support - do not forget to put the plate removed during disassembly in place. Align the landing marks made during dismantling, then tighten the bolts and self-locking nut to the required torque

9. Reinstall the power unit rear support in the reverse order of removal. Tighten the support fasteners to the required torque.

10. Disconnect lifting rigging.

11. Further assembly is carried out in the reverse order of dismantling. Pay attention to the following points:

- a) Follow the correct laying of wiring harnesses, avoiding contact of wires with rubbing or heated surfaces;

- b) Track correctness of a laying and reliability of fixing by collars of all hoses. Replace spring clamps and twist-type clamps with more reliable worm or screw clamps;

- c) When connecting the selector rod, remember to replace the roll pin, and use a worm-type clamp to secure (see chapter Transmission);

- d) The order of filling the cooling system is described in Chapter Current service (depending on engine type);

- e) On diesel models, after connecting the cold start drive cable to the injection pump, do not forget to check and adjust the cold start system.

12. When starting the engine for the first time, check all pipes, hoses and component joints for signs of air, coolant, oil and fuel leaks.

Note. Before starting the engine after a major overhaul, read the notes given in Section The initial start of the engine after the completion of its overhaul.