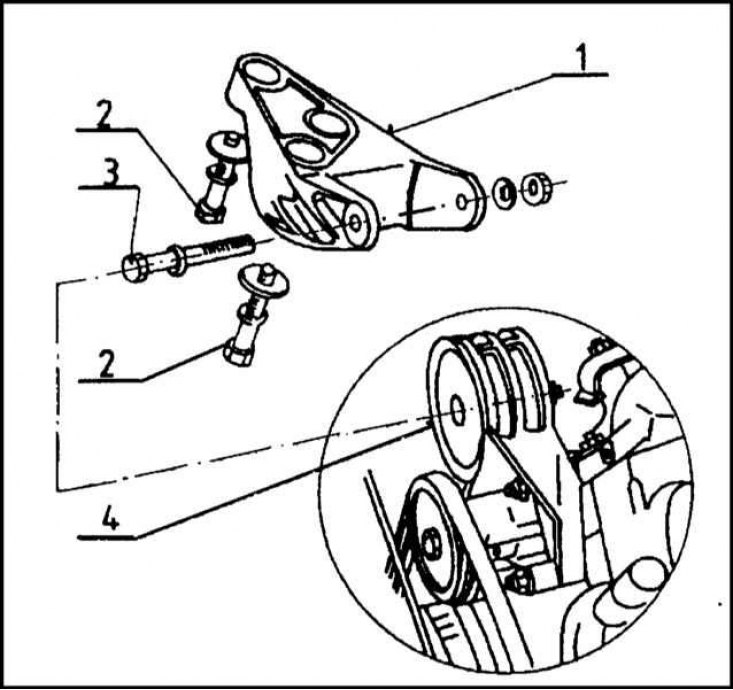

1.3L petrol engine right suspension support

1 - Bracket; 2 - Bolt; 3 - Bolt; 4 - Elastic sleeve

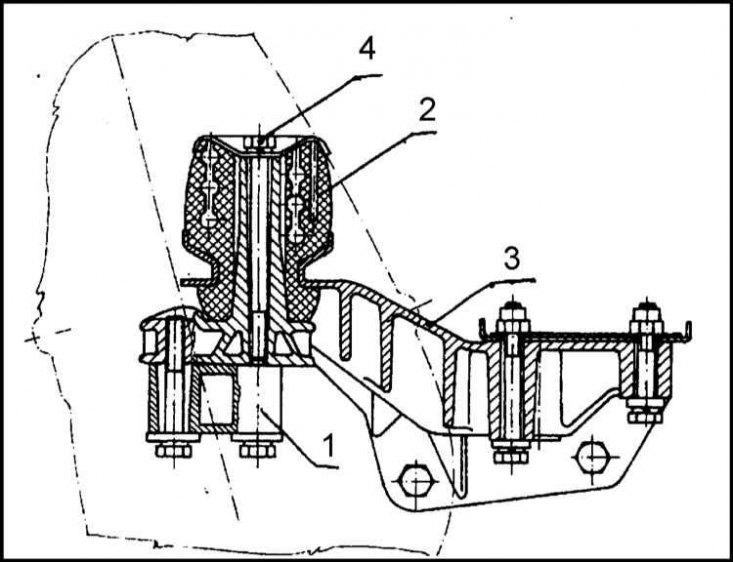

Right suspension support for diesel engine and petrol engine 1.6L

1 - Bracket; 2 - Pillow; 3 - Bracket; 4 - Bolt

Left support of a suspension bracket of the power unit (all engines)

1 - Manual transmission cover; 2 - Elastic sleeve; 3 - Bolt; 4 - Bolt; 5 - Washer; 6 - Bolt; 7 - Washer; 8 - Corner; 9 - Corner; 10 - Bracket; 11 - Bolt; 12 - Washer; 13 - Washer; 14 - Nut; 15 - Bolt; 16 - Washer

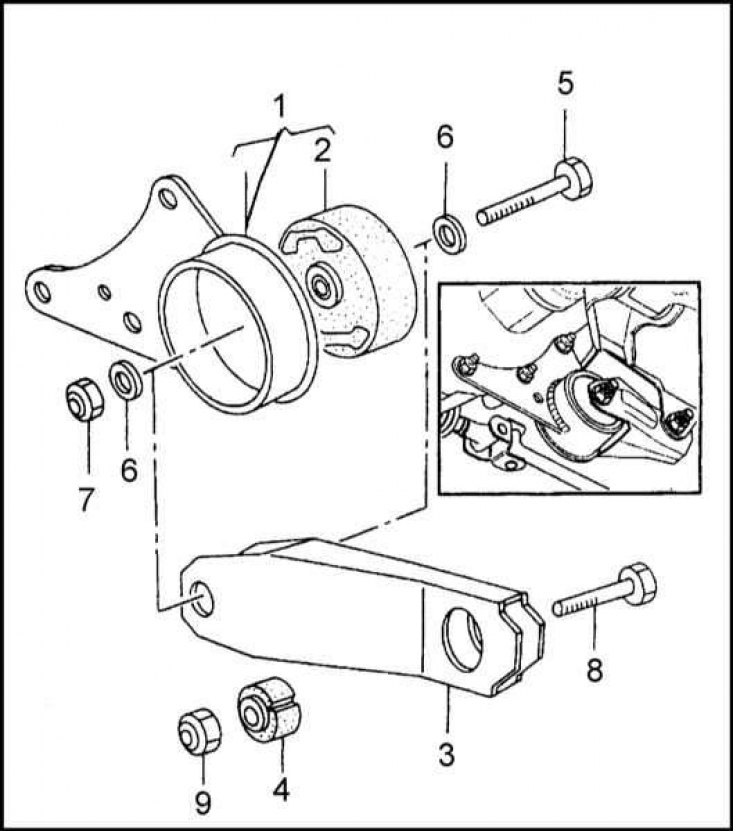

The lower support of a suspension bracket of the power unit (all engines)

1 - Bracket; 2 - Elastic sleeve; 3 - Elastic sleeve; 4 - Reactive lever; 5 - Bolt; 6 - Washers; 7 - Nut; 8 - Bolt; 9 - Nut

Preparation and Precautions

Before proceeding with the dismantling of the engine in order to carry out its general or major repairs, it is necessary to take some preparatory measures.

The presence and equipment of the work site is extremely important. The site must be large enough to accommodate the vehicle, a sturdy workbench/mounting stand, and the necessary materials and equipment. The best option is a large garage or indoor workshop. In extreme cases, just a flat area with an asphalt or concrete surface is suitable.

Care should also be taken to equip a place to store components removed from the engine, tools and other materials. A lightweight collapsible rack with fairly wide shelves is best suited for this purpose.

Before dismantling the power unit, clean the engine compartment and the outside of the engine, which will help keep the tools used clean and tidy.

A winch, A-frame or other suitable lifting equipment is also a prerequisite for successful operation. Make sure that the hoist and rigging correspond in terms of their lifting characteristics to the total mass of the power unit (engine with transmission). Do not forget about the need to strictly comply with safety regulations.

If the engine is removed for the first time by an amateur mechanic, you should enlist the support of an assistant. The timely advice of a more experienced mechanic will be useful. In the process of removing the unit from the car, there are many situations when some procedures must be performed simultaneously, which is often impossible to do by one person.

Try to plan in advance all the moments of the upcoming work. Prepare all necessary tools and equipment. Among the special devices that greatly facilitate the implementation of upcoming work and significantly increase their level of safety, include a powerful trolley jack, a set of wrenches and interchangeable socket heads with a suitable (preferably ratchet) drive, a couple of sturdy wooden blocks, and enough rags and thinner to remove traces of fuel, oil, and coolant. In the absence of lifting equipment for personal use, before renting a winch, try to carry out all the necessary preparatory work in advance in order to minimize the rental period, and, consequently, the material costs associated with it.

Be prepared to not use your vehicle while repairs are being made. Part of the procedures that require highly qualified personnel and the use of special equipment will have to be entrusted to car service specialists. Remember that car repair shops usually have a very busy schedule, and therefore it would be wise to worry in advance and agree with the staff on the timing of your order.

On all Skoda Felicia models, the assembly of the power unit is removed from the engine compartment through the lower opening, and therefore care should be taken to securely fix the car in a raised position when there is enough free space under it. The optimal condition would be the presence of a low overpass on the working site.

Work slowly, in an organized manner, try not to violate basic safety rules!

Suspension of the power unit - general information

The power unit is attached to the load-bearing elements of the car body by means of elastic supports that absorb the vibrations of a running engine and soften the jerks of the unit during acceleration and braking. For all units used on the vehicles in question, a 3-point suspension is provided. The right support of units with a diesel engine and a 1.6 l petrol engine is different from the support of units with a 1.3 l gasoline engine. the lower support, in addition to the vertical load, additionally perceives reactive moments that occur during sudden acceleration or engine braking.

The right support of engines 1.3 l consists of a bracket (1), which is bolted (2) to the left mudguard amplifier. The engine is attached to the support with a bolt (3) through elastic sleeve (4), located in the tide on the water pump housing. The location of the pump above the center of gravity of the engine helps to reduce the level of vibration of the power unit.

The right support of diesel engines and gasoline engines 1.6 l consists of a bracket (1), attached to the cylinder block and connected through an elastic cushion (2) with bracket (3), attached to the body. Central bolt (4) provides the necessary pre-compression of the elastic cushion through the support washer when screwed into the bracket (1).

The left support of the power unit of all engines is made integral with the rear cover of the manual transmission. A hole is provided in the body of the cover support, into which an elastic sleeve is inserted (2). Bushing by bolt (6) and corners (8) And (9) connects to bracket (10), bolted to body (11) And (15).

The lower support consists of a reactive arm (3), bracket (1) and bushings (2) And (4). Required bushing precompression (2) secured by tightening the bolt (5). nuts (7) And (9) are self-locking.