2. Before installing the rings on the pistons, it is necessary to check the size of the gaps in their locks.

3. Lay the piston assemblies and their ring sets on a clean work surface. Lay the cylinder block on its side on a workbench, providing access to both its top and bottom sides.

4. Fill the upper compression ring of the corresponding piston into the first cylinder of the engine. Use the piston crown to push the ring into the bottom of the cylinder. Remove the piston.

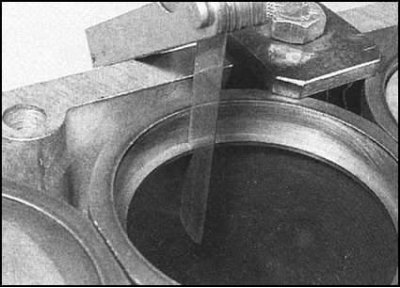

5. Using a blade-type feeler gauge, measure the gap in the lock of the ring - the required thickness of the blade (see specs) should slip tightly between the end surfaces of the ring in its lock. Before discarding a ring, make sure not to confuse it with the bottom one. Repeat the procedure for the remaining rings.

6. When using brand new piston rings, the likelihood that the gaps in their locks will be too small is extremely small - remember that closing locks during thermal expansion of the rings is fraught with engine jamming and irreversible failure. If necessary, adjust the gap by gradually grinding the ends of the ring against the file clamped in a vise - put the ring tightly on the file with a lock and pull it towards you (in no case from yourself in order to avoid the risk of destruction of the ring when the lock is closed). If the measurement result exceeds the allowable value (which in the case of new rings is very unlikely), Before discarding a ring, make sure that you have purchased a set of rings that matches your vehicle's engine size.

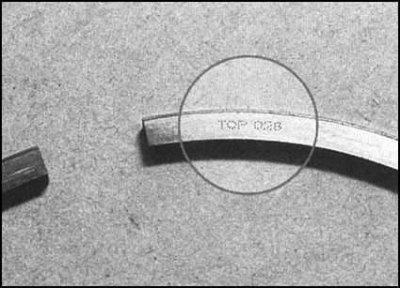

7. After completing the check and adjusting the gaps in the locks of all the rings, you can start putting them on your pistons. The technology of putting rings on the piston is similar to that used to remove them. First of all, the spring expander of the lower (oil scraper) rings, then both of its side sections are installed. Note that both the expander and the side sections of the oil scraper ring can be installed either side up. The second and top compression rings have different cross-sections and can be distinguished from each other by markings applied to their upper side. Make sure that the rings are installed on the piston with the markings up.

8. Having finished installing the rings on the piston, check the freedom of their rotation in their grooves, then turn the locks at 120°to each other.

Note. In case of discrepancy, the installation of the rings must be carried out in accordance with the instructions of their manufacturers.