Clutch

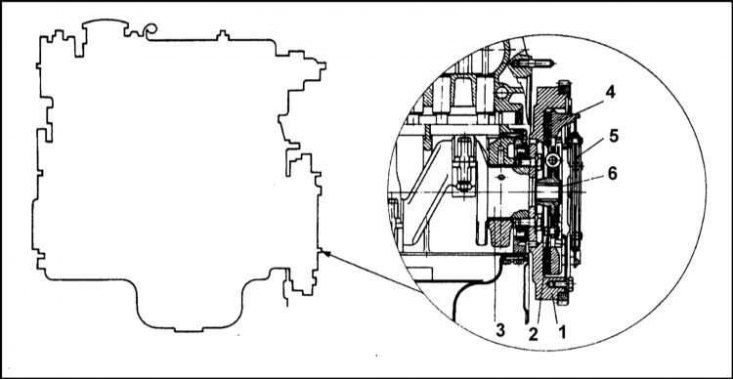

1 - Flywheel; 2 - Clutch disc (friction); 3 - Crankshaft; 4 - Pressure plate; 5 - Diaphragm spring; 6 - Friction disc hub

The clutch consists of a friction disc, more commonly referred to as a clutch disc, a basket assembly with a pressure plate, and a release bearing with a clutch release mechanism. All of these components are housed in a large aluminum alloy casing, commonly referred to as the clutch dome. The dome is sandwiched between the engine and gearbox. The operation of the clutch release mechanism is controlled by a cable drive.

The friction disc is installed between the engine flywheel and the release plate of the corrosion assembly. The disc hub is splined to allow it to move along the splines of the gearbox input shaft trunnion.

The petrol car models in question are equipped with a clutch manufactured by Fichtel &Sachs or Trnava.

The basket assembly is bolted directly to the flywheel. When the engine is running, rotation is transmitted from the crankshaft to the friction disc, which, with the clutch pedal released, is firmly clamped between the flywheel and the pressure plate of the basket, and then to the input shaft of the manual transmission.

In order to break the connection between the gearbox and the engine, loosen the diaphragm spring of the pressure plate, thereby releasing the clutch disc. When the clutch pedal is depressed, the drive cable, acting on the actuating lever located at the top of the clutch release fork, unfolds the latter. Turning, the clutch release fork presses the release bearing against the petals of the pressure plate diaphragm spring. Deforming, the spring weakens the clamping force, which leads to the release of the friction disc. The correct functioning of the clutch is guaranteed by the regularity of its adjustments.

Friction disc linings are made of asbestos-free material. The disc should be installed with the side with the most protruding hub facing out (to casing). clutch cover (basket) is attached to the flywheel with six M8x16 bolts, which should be replaced each time the assembly is removed. Some models are equipped with a TAZ type clutch, which has similar dimensions and differs only in a weaker force developed by a diaphragm spring. Clutch linings of all applied types are interchangeable.

On diesel models, a slightly larger diameter F&S clutch is installed (see specs). The assembly structure is similar to that described above. Friction linings naturally have a large contact area. The pressure spring is also reinforced.

The pressure plate is equipped with additional vibration damper springs (as in TAZ assemblies). The flywheel also has a larger diameter and is equipped with 120°locating pins.

Clutch diesel models and 1.6L petrol models are equipped with a longer release lever (see specs).