Removing

Note. Reassembly will require a new hub nut as well as a replacement lower arm ball joint pinch bolt nut.

1. Remove the rim/hub trim cap, then loosen the hub nut and wheel nuts.

2. Chock the rear wheels, apply the parking brake, then jack up the front of the vehicle and place it on jack stands. Remove the corresponding front wheel.

3. Drain gear oil. After replacing the sealing washer, screw the drain plug of the manual transmission case into its regular place and tighten it with the required force.

4. On ABS equipped models, remove the wheel sensor from the hub assembly (see chapter Brake system).

5. Remove the cotter pin, give the tie rod ball joint nut and release the joint from the pivot arm of the hub assembly (see chapter Suspension and steering).

6. Give a stub nut, remove a washer.

Note. If you are unable to loosen the hub nut before lifting the vehicle off the ground, screw in place and firmly tighten a pair of wheel bolts. Have an assistant firmly apply the foot brake to prevent the hub from spinning, then loosen and remove the hub bolt. The removed hub nut cannot be reused and must be replaced without fail during assembly.

7. On models equipped with a front anti-roll bar, loosen the stabilizer bar strut mounting nut on the lower suspension arm. Remove the washer and remove the lower rubber pad support.

8. On all models, give a nut of a coupling bolt of a spherical support of fastening of the lower arm of a forward suspension bracket to stupny assembly. Using a pry bar, rotate the arm, releasing the pivot from the hub assembly. On models equipped with an anti-roll bar, take care not to drop the upper rubber cushion and the washer of the rod mount. The coupling bolt and its nut must be replaced without fail during assembly.

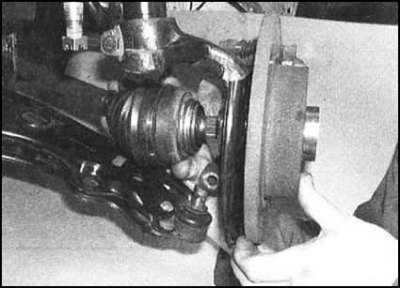

9. Carefully pull the hub assembly outward, removing it from the driveshaft outer CV joint splines. If necessary, the shaft can be knocked out of the hub with a soft-faced hammer. Immediately tie up the released shaft with wire to the suspension elements to avoid damage to the inner joint and its protective cover.

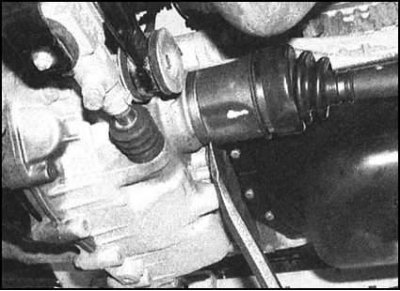

10. Taking care not to damage the crankcase, gently pry the inner CV joint with a pry bar or large screwdriver and release the inner shaft journal from the differential assembly.

11. Remove the shaft from under the car (try not to damage the differential seal).

Note. Never lower the vehicle to the ground after removing one or both drive shafts. This practice is fraught with failure of the wheel bearings. If it becomes necessary to move the vehicle, temporarily insert the outer end of the shaft (ov) into the hub of your wheel and secure it with a nut, then tie the inner end with wire to the suspension elements.

If it is necessary to remove both drive shafts, care must be taken to fix one of the side gears in the differential box. Having removed the first of the shafts, thread a suitable diameter into the hole in the crankcase (about 26 mm) rod by passing it through the hole in the gear. Leave the other end of the rod protruding freely from the box. If one or more gears fall inside the assembly, the gearbox will have to be disassembled to remove them.

Installation

1. Before installing the drive shaft, check the condition of the oil seal of its seat in the differential housing. Replace seal if necessary (see Section Replacement of oil seals).

Note. The compilers of this Guide recommend replacing oil seals, regardless of their condition.

2. Using a small screwdriver, remove the CV joint retaining ring from the end of the inner shaft pin and install a new one in its place. Track the correct fit of the ring in the groove.

3. Thoroughly wipe the splined part of the trunnion and the surface of the walls of the hole in the differential case. Lubricate the packing lips, splines, and shaft shoulders with a thin layer of grease. Make sure that the rubber protective cover of the CV joint is securely fixed with bandages.

4. Being careful not to damage the oil seal, engage the shaft with the splines of the differential side gear hub in the gearbox. Push the shaft into the box until it stops and make sure that it is securely fixed with a retaining ring. If necessary, use a soft-faced hammer to seat the shaft.

5. Align the outer CV joint and push its trunnion into the hub assembly. Fit the washer and screw on the hub nut, finger-tight for now.

6. Use the lever to press the lower suspension arm assembly down, tuck the ball joint into place, then release the lever. Make sure that the ball pin of the support is fully inserted into its seat in the collar of the hub assembly. Insert the tie bolt, screw the nut onto it and tighten it to the required torque. On models equipped with an anti-roll bar, install the stabilizer bar post onto the lower arm assembly, making sure the top rubber pad and washer are properly seated.

7. Where required, reinstall the bottom rubber pad and anti-roll bar post washer, install the nut and tighten to specification.

8. Insert the tie rod end into the pivot arm of the hub assembly and secure it with your nut, firmly tightening the latter. Secure the nut with a new cotter pin.

9. On models equipped with ABS, install the wheel sensor on the hub (see chapter Brake system).

10. Reinstall the wheel, lower the vehicle to the ground and tighten the wheel bolts to specification.

11. Tighten the hub nut to the required torque, then reinstall the wheel/hub trim cap.

12 Fill the gearbox with the correct amount of gear oil of the correct grade.