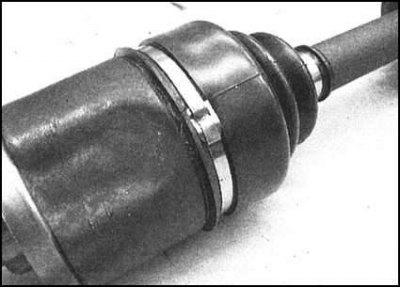

Outer CV joint

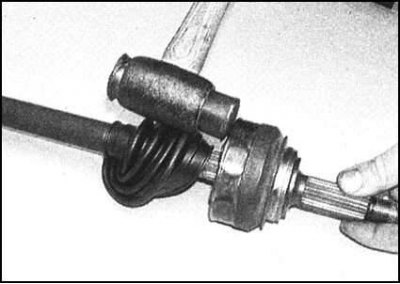

2. Clamp the drive shaft in a vice with soft jaws and release the bandage tapes securing the protective cover of the outer CV joint.

Note. If necessary, bandage tapes can be simply cut off.

3. Turn away a cover so that access to the hinge opened. Remove excess lubricant.

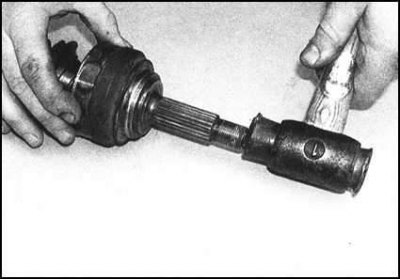

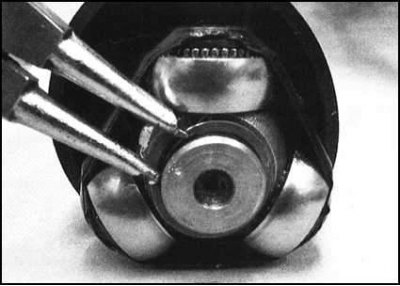

4. With sharp hammer blows through the punch on the inside of the hinge, knock the latter off the shaft. The hinge is fixed on the shaft with a retaining ring. When the assembly is knocked down in the described way, the ring falls into a specially provided groove on the shaft, which allows you to freely remove the CV joint.

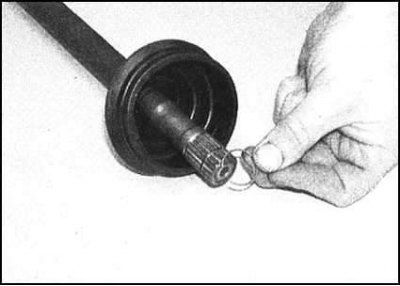

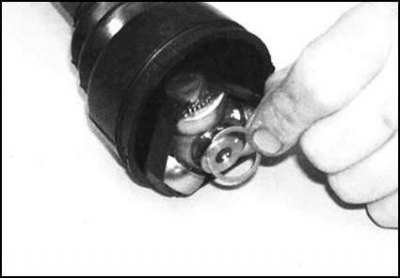

5. After removing the hinge, remove the retaining ring from its groove and discard it - during assembly, the ring must be replaced without fail.

6. Remove the CV joint rubber protective cover from the shaft.

7. Thoroughly wash the removed hinge with kerosene or other suitable solvent. Perform a visual inspection of the condition of the assembly's internal components.

8. Moving the inner part of the hinge, inspect each of the balls in turn in their upper position. Pay attention to cracks, flattening and cavities.

9. Check the guides in the inner and outer races of the assembly for developed areas where the tightness of the balls is violated. At the same time, check the condition of the separator - the presence of cracks between the windows is unacceptable.

10. A worn or damaged hinge must be replaced. If the CV joint is deemed fit for further use, prepare a new protective cover, bandage bands, a retaining ring and grease for the CV joint packing (see specs).

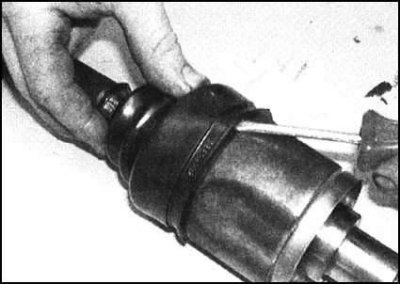

11. Wrap the splines of the trunnion with adhesive tape and carefully put a new protective cover of the CV joint on the shaft. Try in the process of putting on the cover to prevent displacement of the plastic bushings installed in its inner sponges.

12. Remove the tape and fit a new circlip onto the shaft. Check that the ring fits correctly in the groove on the shaft.

13. Pack the hinge with fresh grease. Pour the grease remaining in the package into the case.

14. Push the CV joint onto the shaft pin and slide its edge from above onto the retaining ring. With sharp blows of a soft-faced hammer on the outer part of the hinge, place the latter on the shaft. After pulling the assembly, make sure that it is securely fixed on the shaft with a retaining ring.

15. Place the outer lips of the boot into the groove on the CV joint assembly, fasten the inner lips to the shaft shoulder. Raise the inner edge of the cover to let the air out from under it.

16. Make sure the cover fits correctly, then secure it with bandage tapes.

Note. Bandage tapes of two types are issued.

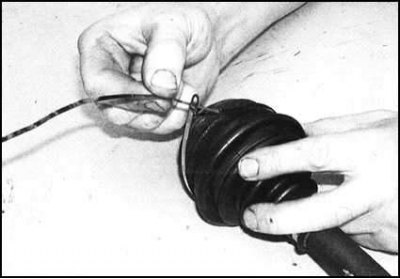

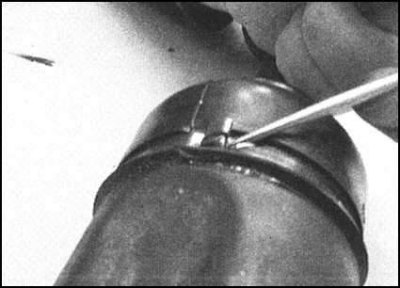

17. Most often, for fastening the protective covers of CV joints, bandage tapes are used, which are simply wrapped around the cover and fixed by squeezing the protruding sections. In the absence of a special tool, the clamps of the bandage can be compressed using pliers or side cutters (be extremely careful not to accidentally cut the tape).

18. Bandage tapes in the form of metal strips equipped with a buckle at one end are less common. After wrapping around the case, the free end of the tape is passed through the groove in the buckle. Having correctly placed the tape on the cover, arm yourself with a special hook made from a welding electrode and pliers. Having tightly wrapped the cover with tape, bend back its free end and throw it over the buckle. Use the side cutters to cut off the excess tape behind the buckle, then press firmly on the remaining "tail" down.

19. Make sure that the cover is securely fixed, then check the freedom of rotation of the hinge in all directions. Now the shaft can be installed on the car (see Section Removal and installation of power shafts).

Internal CV joint

1.Clamp the shaft in a vice with soft jaws and release the bandage tapes securing the protective cover of the inner CV joint.

Note. If necessary, the tapes can be cut.

2. Turn the boot back to expose the hinge. Wipe off any excess grease, then use paint or a marker to mark the position of the pivot housing relative to the shaft.

3. Remove the end shell from the hinge body and slide the body off the shaft. Try to prevent the rollers from falling out of the tripod assembly - wipe the latter and wrap it around the outside with tape.

Note. Installing all the internal components of the hinge in exactly the same order is extremely important, so care must be taken to maintain the installation position of the tripod assembly during the removal of the case. Violation of this requirement can lead to a significant reduction in the service life of the CV joint.

4. Remove the outer housing shell from the shaft by dropping it over the tripod assembly. Try to remember the installation position of the shell.

5. Mark the position of the tripod assembly in relation to the shaft. Loosen the retaining ring and remove the assembly from the shaft journal. If the tripod is too tight on the shaft, use a 2-leg puller to remove it. The grips of the legs of the puller are brought under the inside of the assembly - do not allow the knife to contact the rollers. Alternatively, support the inside of the assembly and press the shaft out of it with a hydraulic press - never apply a load to the rollers.

6. After removing the tripod assembly, the hinge cover can be removed from the shaft.

7. Thoroughly wash the hinge components with kerosene or other suitable solvent - be careful not to wash off the landing marks. Perform a thorough inspection of the hinge.

8. Check the cross and rollers of the tripod assembly for signs of wear. Inspect the outer casing and its end shell. Appreciate the freedom of rotation of the rollers. If any defects are found, replace the joint. If the CV joint is deemed fit for further use, prepare new bandages, a protective cover, a retaining ring and the required amount of lubricant of the required grade (see specs).

9. Wrap the shaft stud splines with adhesive tape. Carefully put the CV joint protective cover on the shaft, placing it in the receiving groove.

10. Remove the adhesive tape, and put the shell of the outer hinge housing on the shaft (make sure that the shell is deployed in the correct way).

11. Seeking to align the landing marks made during dismantling, put the tripod assembly on the splines of the shaft pin. Gently tap the assembly into place (use a hammer and a soft metal drift). Take care not to damage the splines and the shaft and hinge rollers.

12. Secure the tripod assembly to the shaft with a new circlip. track the correct fit of the ring in its groove.

13. Remove the tape wrapped around the rollers, then put on the outer hinge housing.

14. Follow the alignment of the landing marks applied during dismantling. After making sure that the components are installed correctly, secure the case with the shell.

15. Evenly lubricate the cavities of the tripod assembly and the outer hinge housing. Drive the rest of the grease into the case.

16. Insert the outer lips of the protective boot into the groove on the outer hinge housing, then gently lift the edge to release the air.

17. In accordance with the instructions given in paragraphs 17 and 18 of the subsection External SHRUS, secure the cover with two bandage tapes.

|  |

18. Check the freedom of rotation of the CV joint in all directions, then install the drive shaft in its regular place on the car (see Section Removal and installation of power shafts).